What is the function of plastic granulator?

The plastic granulator is a very great invention because it not only creates benefits for the user, it also makes a significant contribution to our environmental protection. In the past, waste plastics were generally disposed of by incineration and landfill, but these two ways can easily damage our ecological environment.

How to turn plastic into pellets? (granulation process)

The discarded plastic is subjected to crushing via a plastic crusher, subsequently conveyed to the feeder through an automated lifting system. The feeder then transfers the material to the plastic granulator machines. Upon entering the granulator, the material is subjected to blending and re-plasticization, brought about by the screw’s compression and external heating mechanisms.

Then the plastic strands will be extruded by the model head of the granulator machines. A cooling tank can rapidly cool the plastic by cold water and solidify them. Once cooled, they are cut into smaller, uniform-sized pellets using a granule cutter.

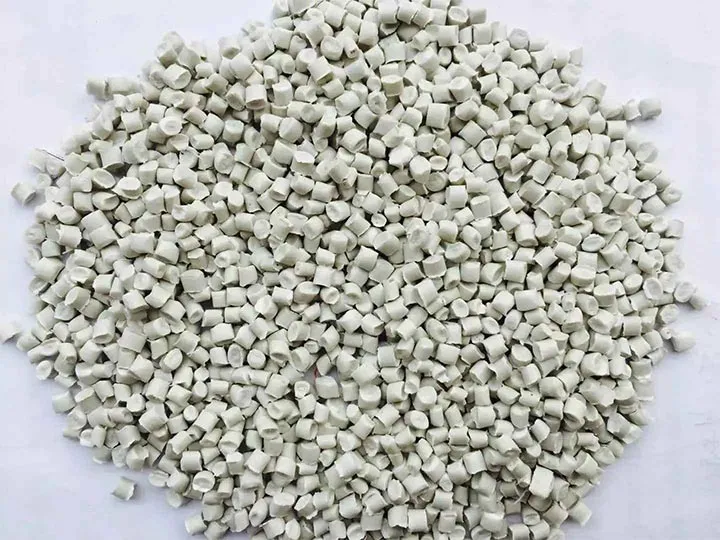

Final granules you obtain

High-quality plastic granules are characterized by uniform granule size and shape, highly stable chemical properties, and low impurity content, and undergo rigorous quality control to ensure they meet specific application requirements. These pellets typically exhibit good flowability, heat resistance, and mechanical performance, making them widely used in the production of various plastic products.

Application for plastic granulation equipment

For blown film producer

Remaining edge waste from blown film, film rolls and sheets can be efficiently recycled in a simple process. High-quality, even-sized recycled granules are almost like virgin material, they can be put right back into the film production line.

For PP woven bag/sap/tape producer

In-house (post-industrial) waste is generated during the production of PP woven bags, PP raffia, nonwovens, container bags, PP woven bags, PP ropes, etc. Recycled PP pellets by industrial granulators can be reused for film production.

For plastic recycling center

Plastic recycling centers and recycling plants collect post-consumer and post-industrial waste. These plastics are more heterogeneous and of poorer quality. After a series of treatments such as sorting and cleaning and crushing, the recycling plant will improve the granule quality by adding masterbatch or additives.

What are the damages caused by the previous treatment of plastic waste?

Generally, plastic waste after landfill takes millions of years to fully degrade. In this long period, waste plastic can easily contaminate groundwater and cause incalculable damage to the local environment. If we choose to burn plastic waste, it is easy to cause damage to the atmospheric environment. Toxic gases are generated when plastic is burned. For example, when polystyrene is burned, toluene is produced. A small amount of toluene causes blindness and inhalation symptoms. When PVC is burned, some toxic gases are also produced, such as hydrogen chloride. In addition, high-temperature environments can also cause the plastic to decompose toxic components, such as benzene rings. Therefore, it is imperative to use plastic granulators for plastic recycling.

Plastics granulator video

The video shows the 1000kg/h plastic pelletizing line, the main recycling machines are plastic film crusher, a washing tank of 30 meters, an SL-220 plastics granulator machine and granules cutter.

We can also offer packaging machines for your special demands. The granules in the following video are packed into bags with 10kg each bag.

The important role of plastic granulator:

As a new plastic reprocessing method, plastic granulation will definitely become the new direction for plastic recycle in the future,it uses a plastic granulating machine to avoid white pollution, incineration and so on.

With the progress of the ages, white pollution has become increasingly serious, and waste plastics are everywhere, which wastes resources and seriously pollutes the environment. So the granulating of waste plastic provides us with a broad investment profit margin. Taking a lead must bring us good returns. The never-saturated market maximizes your investment.

Waste plastic granulators are now recognized by most customers. Recycling and granulating plastic using a plastic granulator is a new model for the development of waste plastic. The machine is mainly used for granulating waste plastic film, plastic bulks, PP raffia bags, woven bags, agricultural bags, pots, barrels, beverage bottles, furniture, daily necessities, etc. It is suitable for most common waste plastic. It is the most widely used and most popular plastic recycling machine in the waste plastic recycling industry.

Plastic granulating capacity

Features of our plastic granulator are large output, long service life, and small footprint. Plastic granulators can process about 1000-500kg of waste plastic per hour, which is the most ideal equipment in the plastic recycling industry. If you have an interest in our plastic granulator or a complete recycling line, please leave us a message below.

Industrial recycling granulator for sale

Shuliy Machinery has manufactured and extorted plastic granulation machines for over twenty years, we have assisted many clients to begin their plastic recycling plants and make profits from selling high-quality plastic granules.

If you are also interested in plastic recycling machines and plastic granulators, send us a message by our website popup. our project manager will contact you in 24 hours and meet your plastic granulating needs.