Fibre Shearing Machine | Fiber Shredder for cutting waste cloth

Fibre Shearing Machine | Fiber Shredder for cutting waste cloth

The fiber shearing machine can cut worn-out clothes between 5—300mm, and the output is about 300—1500kg per hour. It can be used for all kinds of waste fabrics, old clothes, cotton fiber, fiber, linen, silk-back leather, cartons, and plastic films. The multi-piece rotating knife reduces the cost of machine wear and replacement and ensures the reliability of a large amount of material shearing.

Fibre shearing machine description

The fiber shearing machine can be used to cut all kinds of fiber rags. Such as glass fiber, aramid fiber, synthetic fiber, and so on. The fiber waste cutting machine has one fixed blade and two movable blades. With the help of the high rotation of movable blades roller, the raw material will be cut into small pieces when they pass the fixed blade.

The fiber shearing machine is made and designed on the basis of better character and advanced experience of the similar product domestic and abroad. In addition, it can meet the requirement of the best quality, high output, low cost and also has a feature of reasonable structure, easy operation and safe production and so on.

What is the use of a Fiber shredder for cutting waste cloth?

Garment scraps, cotton spinning scraps, all kinds of waste clothes, leather cutting.

The fiber shredder can quickly shred various car interiors, woven bags, diapers, waste cloth heads, cotton spinning waste yarn, waste clothing, cotton wool, chemical fiber, linen, leather, plastic film, paper, trademarks, non-woven fabrics, etc. The chopped materials are uniform in size.

Technical parameter of Fibre shearing machine

| Model | Capacity | Power | Cut size | Cut thickness | Dimension |

| SL-300 | 300kg/h | 3kw | 5—300mm fixed one size | 20mm | 1865*1120*1220mm |

| SL-500 | 500kg/h | 4kw | 5—300mm fixed one size | 20mm | 3220*1160*1260mm |

| SL-800 | 800kg/h | 5.5kw | 5—150m Select 3 sizes | 30mm | 3500*1200*1300mm |

| SL-1500 | 1500kg/h | 9kw | 5—150m Select 3 sizes | 30-60mm | 6000*1000*1100mm |

Features of Fiber shearing machine

- Wide range of applications, stability, and reliability

It is suitable for multiple industries and meets the needs of different industries. The products use a variety of special materials and are precision processed through hundreds of procedures to ensure the safety and stability of the machine, greatly improving production efficiency, replacing labor, and freeing hands.

- Advanced technology and long service life

The use of advanced manufacturing technology and advanced digital component processing equipment ensure the precision of machine components; the selection of high-quality materials greatly increases its pressure resistance and wear resistance, and greatly extends the service life of the machine.

- Simple equipment structure and easy to maintain

After continuous improvement and optimization, while ensuring the performance of the machine, the machine structure is also simplified. The whole machine is easy to operate, convenient to maintain, and downtime for maintenance is greatly shortened.

- High cutting accuracy

The pressure wheel is in contact with multiple blades at the same time, and the cutting efficiency is high.

- Simple design of cutter head

It is easy to maintain and can be adapted to various cutting requirements. The blade has a large working length and high cutting capacity.

Because the rotary knife adopts multiple pieces, the wear and replacement cost of the blade is reduced, and the reliability of cutting a large number of materials is guaranteed

- Reasonable design, durable and stable performance.

There is no high requirement on the cut tow, and it can process various specifications and forms of materials and even various types of leftover materials.

After the fibers are cut, they fall vertically in a free state, and the noil is relatively smooth.

Related machine

Hot Product

PET bottle crushing machine

PET bottle crushing machine plays a very important…

Plastic Bag Shredder Grinder Machine

A plastic bag shredder is a kind of…

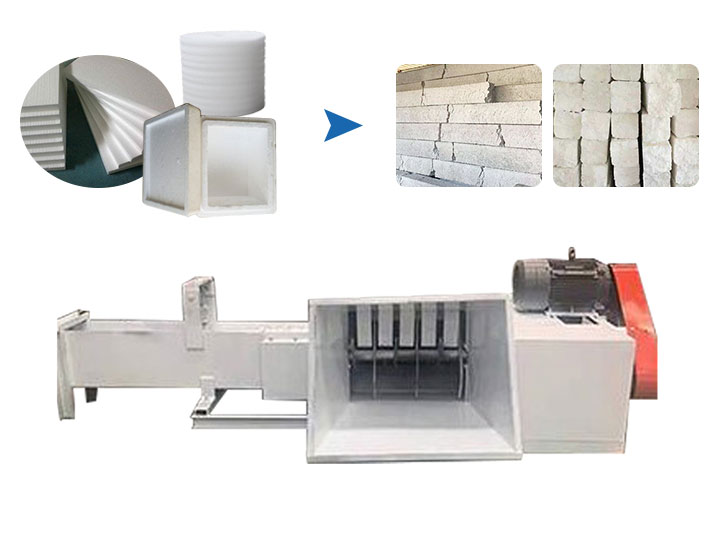

Horizontal EPS foam compactor

The function of the horizontal EPS foam compactor…

Strand Pelletizer Machine for Rigid Plastic Recycling

Strand pelletizer machine offer recycled pelletizing technology for…

Frictional washing machine for PET bottle recycling

Working process of the frictional washing machine As…

PET Bottle Washing Plant Machinery

Our PET bottle washing plant is a suitable…

Manual powder coating booth

The manual powder coating booth is a small…

Pioneering waste plastic water ring pelletizer

Due to the advantages of the water ring…

Waste tire recycling line | rubber granules making machine

The waste tire recycling line uses advanced tire…