Shuliy Machinery focuses on manufacturing and developing plastic recycling machines, including plastic washing pelletizing lines and plastic pelletizing machines. Our plastic recycling pelletizing machines for plastic film and rigids have won a high reputation from customers for their advanced technology, suitable price, great performance, and thoughtful after-sale services.

We do everything possible to provide superior plastic pellets with higher value, let our plastic recycling machines help global customers improve production efficiency, and create higher profits from plastic recycling.

Read More

Shuliy\'s high-efficiency plastic recycling lines are designed for both post-industrial and post-consumer waste. Our machines can recycle defective blown film production waste, bag cut-offs, edge trims, regrind plastic waste from injection and extrusion, automotive and electronic waste, etc. The material types include PP HDPE, LDPE, LLDPE, ABS, EPE, EPS, PC, PA, PVC, etc. The final products are recycled granules, they have wide applications such as film blowing, injection molding, pipe extrusion, filler and so on.

Application: post-industrial recycling, post-consumer recycling

Applicable materials: soft irrigation pipes, bag scrap, printed bags, film-on-rolls, waste plastic films, used agriculture films, shopping T-shirt bags, jumbo bags, woven bags, etc.

Output: 100-500kg/h

Material type: PP, LDPE, HDPE, LLDPE, PVC

Main equipment: crusher, PE film washing machine, granulator,pellet cutter

Warranty: 12 months

Capacity: 100-500kg/h (Support larger output requirements)

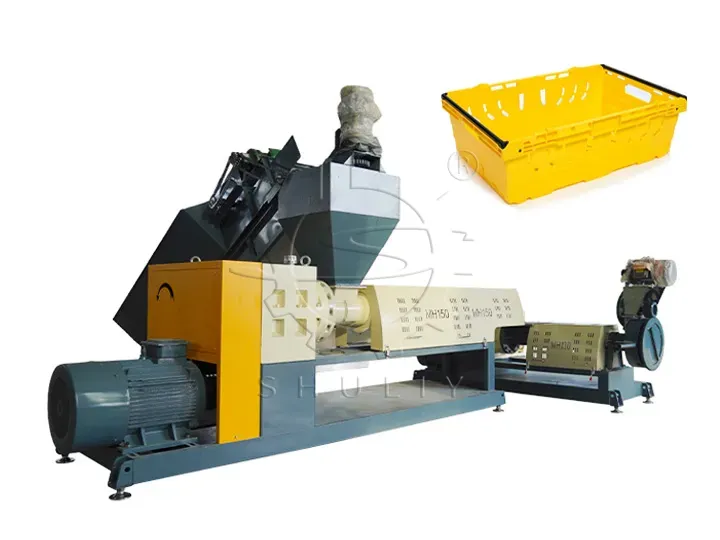

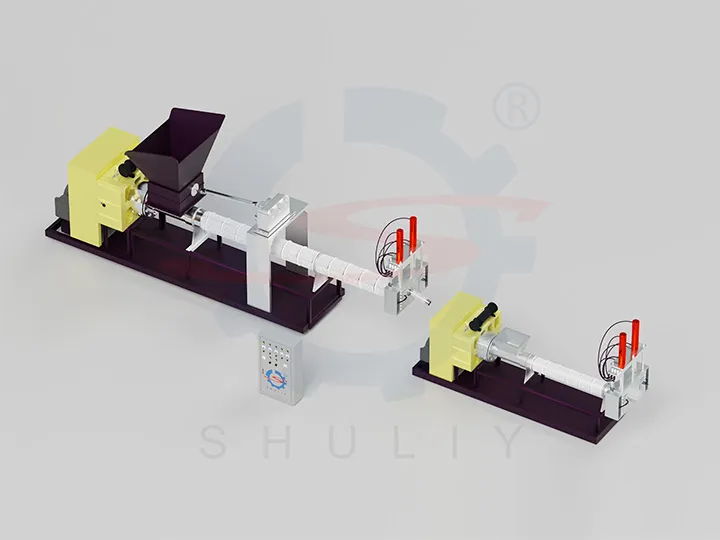

Recycle materials: plastic regrind, milk bottles, drums, car bumper, boxes, injection molded products, blow-molded products, electronic waste, automatic waste, cosmetic tube, food container, pallet, pipe

Material type: PP, HDPE, PVC, PS, PA, ABS

Optional equipment: scew feeder, belt conveyor. granule silo

Service: design, installation, training and tracking service

Waranty: 12 months

Machine brand: Shuliy

Raw materials: PET baverage bottles, water bottles

Output: 500~6000kg/h

Final product: clean PET flakes

Warranty: 12 months

Service: determine the plan, delivery, installation, training and tracking

Raw materials: waste EPE foam, waste EPS foam

Output: 150-300kg/h

Main equipment: plastic foam crusher, foam granulator

Final products: recycled EPE, EPS pellets

Warranty 12 months

Machine brand: Shuliy

Different equipment provides different recycle solutions. Our plastic recycling machines help you obtain superior plastic pellets for higher profits. The better plastic pellets will not only expand your profit margins, but also assist you in earning trust of your customers.

It is suitable for different types of plastic films, such as PE, PP, PVC, etc., with strong adaptability.

Provide drawing design for complete plastic pelletizing line

The final plastic granules can be directly used to produce plastic products

Suitable for both soft and rigid plastics

Capable of handling all types of plastic scrap: film, bottles, containers, pipes, etc.

Work parameters can be adjusted: e.g. blades spacing, shredding size, etc.

Support wet crushing of film materials

Shuliy recycle machines are all CE certificated

Various plastic recycling projects are abailable, big or small!

20 years manufacture experience + 200 customers

Cutting speed and tool spacing can be precisely adjusted to ensure consistent granule size.

Relatively simple operation, the operator can easily master the use of the granules cutter

Various available recycle materials: PP raffia, woven bags, PP PE bags/films, pipes, HDPE rigid plastics, etc

Provide online/on-site instructions for your recycling machines

All recycling machines are CE certificated

Various machine models: Meeting output of your plants

The internal material is made of corrosion-resistant material, which can operate stably in high temperature and humid environment.

High temperature cleaning can effectively remove residual substances and ensure product quality.

Speed can be adjusted to suit different sizes and types of PET bottles.

Can be combined with other recycling machines to form a complete plastic bottle recycling line

Equipped with advanced automatic control system, it can realize automatic feeding, de-labeling, discharging and other operations.

Nearly all kinds of plastic bottles can be crushed

The cutting angle of the grinder is precise, which improves the shredding efficiency and less powder

PET bottle scrap grinder machine price is favorable

Flattened bottles and bottle brick are both available

We are proud of shipping and installation 80 plastic recycling machines worldwide. The recycling plants we cooperated mainly recycled woven bags, PP PE plastic films, PP raffia bags, bag scrap, rigid plastics and PET bottles. Shuliy help them obtain recycled plastic pellets of high quality and pure PET flakes. The end products can be directly processed in the plastic production line.

At Shuliy Group, we understand that every region faces unique challenges when it comes to recycling plastic waste. In many…

Feb - 26 - 2025

read more

1

Focusing on export for many years, fast delivery and fantastic after sales services

2

Plastic recycling machinery is sold well worldwide, helping over 80 recycling plants installation

3

Recycling machines and services are trusted by customers

We warmly welcome you to visit our factory and learn more about our plastic recycling machinery and recycle systems. If you have any questions or needs about our machine, please feel free to contact us, we will be happy to serve you!

Shuliy devoted ourselves to offer useful knowledge for beginners in recycling business. Meanwhile, we provide available recycle solutions for recycling experts. We put all my recycle industry knowledge into this News part, helping you understand plastic knowledge, recycle process, machines purchasing tips, news in recycling industries etc.

Agricultural drip irrigation tapes and pipes are core tools of modern precision agriculture, dramatically increasing crop yields and resource utilization through efficient water conservation and precision irrigation. When large quantities…

Mar 27 2025

Read More