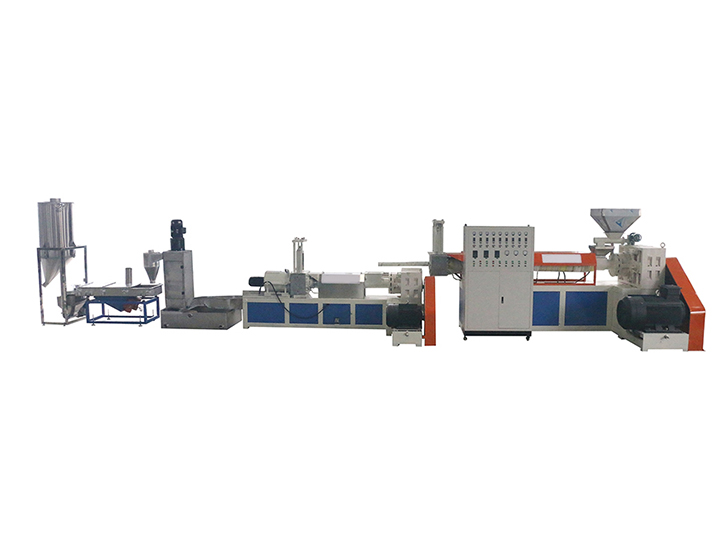

Application of plastic granulator smoke eliminator

Waste plastic granulator in working state During the melt extrusion process, waste smoke, and waste gas is discharged through the exhaust port and discharge port of the plastic granulator, and are connected to the plastic smoke remover through the smoke collection chamber and pipeline. At the same time, consider that the plastic smoke removal equipment itself needs a water supply and drainage, so it needs to be placed in a favorable water supply and drainage position and should be as close as possible to the smoke discharge to minimize the length of the connection pipeline.

Application of plastic granulator smoke eliminator

At the same time, the venting and discharge openings of the plastic granulator should have a good effect on the smoke collection compartment. The collection compartment should be sealed as much as possible to reduce the emission of smoke, and the smoke can be effectively collected and smoothly sucked into the pipeline.

Finally, it is smoothly sucked into the ternary smoke removal system under the vacuum negative pressure; the hose between the smoke collection chamber and the plastic smoke remover on the plastic granulator can be connected by hose, and the hose specification is required to be matched with the pipe fittings at the interface as much as possible. And wrap the sealing interface, and at the same time require the hose to have sufficient strength to withstand a certain pressure, so as to prevent the hose from being crushed during normal working suction.

The above is about the introduction of the plastic granulator smoke eliminator, I hope to help you.