Cotton Waste Recycling Machine | Garment Rags Tearing Machine

Cotton Waste Recycling Machine | Garment Rags Tearing Machine

The cotton waste recycling machine is mainly used for the cleaning and recycling of yarn, linen, cloth, chemical fiber, and other fibers. The new machine has a scientific and reasonable structure, safety, reliable performance, stable operation, and simple operation. Large output, good cleaning effect, low consumption, environmental protection, and low noise. The textile waste scutching machine can match with the fibre shearing machine.

How is textile waste recycled?

Spread the cotton wool to be processed evenly on the cotton feeding curtain and send it to the roller. Due to the rotation of the roller, the cotton layer is continuously fed under the strong grip of the cotton roller. When the hooking and rubbing force of the saw teeth on the cotton wool are greater than the holding force it receives, the fibers that have been carded out in the cotton wool are gradually taken away by the roller. The cotton wool is separated into a single fiber state, and under the action of the high-speed rotation of the roller, a large centrifugal inertial force is generated. Impurities will be continuously thrown out along the tangent direction of the outer circle of the drum.

Application range of cotton waste recycling machine

This textile waste recycling machine can be widely used in a variety of chemical fiber, linen spinning, cotton spinning, wool spinning, textile waste yarn, waste clothing, textile scraps, non-woven fabrics, and other raw materials. It is suitable for industries such as textiles, toys, clothing, shoemaking, knitted chemical fiber, waste processing, and so on.

Garment Rags Tearing Machine features

- The application of the reducer has strong adaptability to long-term processing, does not generate heat, and has a long life.

- The new rack design and configuration, which integrates the combined work model of “breaking-opening-double cleaning-double combing”, progressively process the raw materials, reduce fiber damage, and greatly increase the fiber length.

- The special structure of the roller and the arc rib-shaped cotton feeding board have a long service life.

- The gap is easy to adjust and maintenance is convenient.

- Bold rollers, four-roller cotton feeding mechanism, barbed roller type and other feeding forms can be selected at will for different raw materials.

Cotton waste recycling machine parameter

| Name | Type(GM) | Size(mm) | Power | Roller length | Roller diameter | Weight | Capacity (kg/h) |

| One roller | 1010 | 2000x1700x1150 | 5.5kw | 1000 mm | 250mm | 500kg | 100-200kg |

| Two rollers | 210 | 2900x1700x1150 | 11kw | 1000 mm | 250mm | 1000kg | 100-200kg |

| Three rollers | 310 | 4000x1700x1150 | 16.5kw | 1000 mm | 250mm | 1500kg | 100-200kg |

| Four rollers | 410 | 5100x1700x1150 | 22kw | 1000 mm | 250mm | 2000kg | 100-200kg |

| Five rollers | 510 | 6200x1700x1150 | 27.5kw | 1000 mm | 250mm | 2500kg | 100-200kg |

| Six rollers | 610 | 7300x1700x1150 | 33kw | 1000mm | 250mm | 3000kg | 100-200kg |

Maintenance of cotton waste recycling machine

- Fancy square cloth: add oil twice per shift.

- Sliding bearing and tensioning sprocket: add a few drops of HJ5 mechanical oil every day.

- Refuel the reducer in a proper amount. It is better to put the oil on the big gear when turning by hand. Clean and change the oil every six months, and often open the small top cover to check the amount of oil in the tank.

- The chain drops a few drops of oil per shift to maintain an oil film.

- When the cotton waste recycling machine is first used, lubricate every part; after a long period of time, re-use it, clean the reducer and change the oil.

Garment rags tearing machine exported to Bangkok

In mid-August, the customer sent us an inquiry for a cotton waste recycling machine. After detailed exchanges, we learned that he runs a small textile waste recycling plant. Previously, he used small textile scraps recycling machine. The working speed is slow, and the recycling volume is uneven. Therefore, he decided to purchase automatic garment rags tearing machine.

After understanding the customer’s needs, we recommended this textile waste scutching machine to him. His recycling capacity is 200kg/h and the roller diameter requirement is 250mm. This cotton waste recycling machine can fully meet his needs.

Hot Product

Rubber powder production line | waste tire recycling plant

The rubber powder processing line is specialized for…

EPE Recycling Machine for Foam Pelletizing

Waste EPE foam pelletizing machine is suitable for…

EPS/Styrofoam Densifier Hot Melting Machine

Descriptions of the styrofoam densifier The styrofoam densifier…

Plastic pellet bagging machine | Packing machine

Waste plastic needs to be packaged completely after being processed…

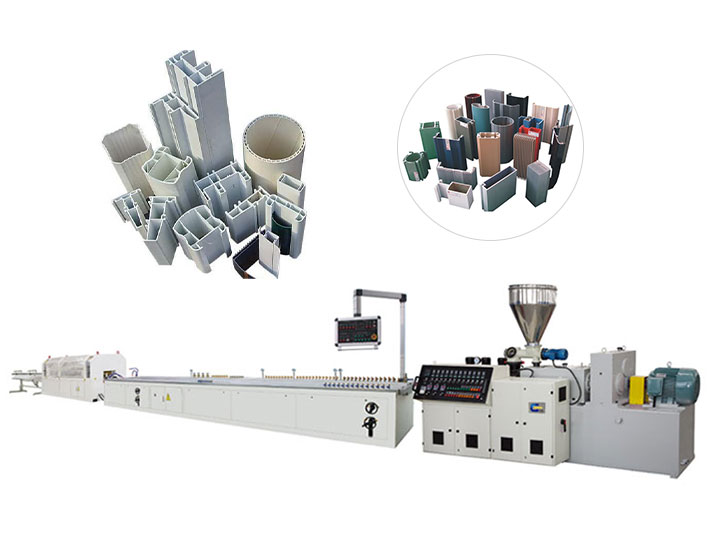

Plastic profile extrusion line | PVC ceiling making machine

Shuliy plastic profile extrustion line is a professional…

Belt conveyor | Plastic bottle sorting table

Structure of belt conveyor The belt sorting table…

Vertical foam cutting machine

The Vertical foam cutting machine is dedicated to…

Plastic Pelletizing Machine

The plastic film pelletizing machine can also be…

Plastic Pellet Making machine

A plastic pellet making machine is a recycling…