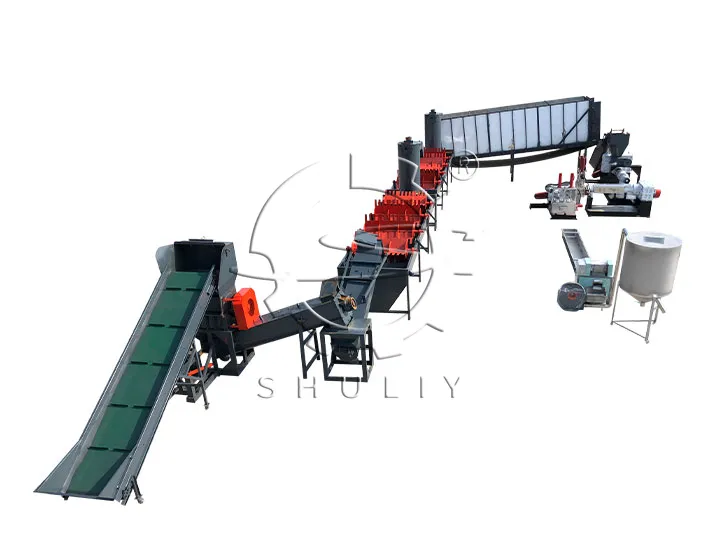

EPS/Styrofoam Densifier Hot Melting Machine

EPS/Styrofoam Densifier Hot Melting Machine

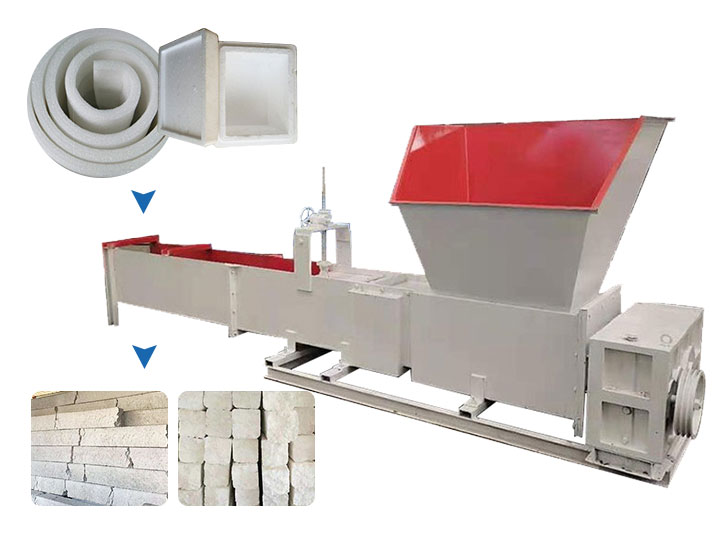

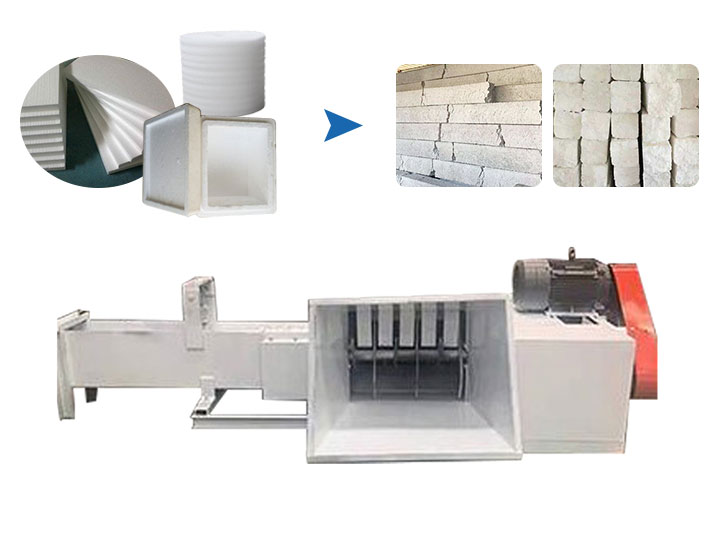

Descriptions of the styrofoam densifier

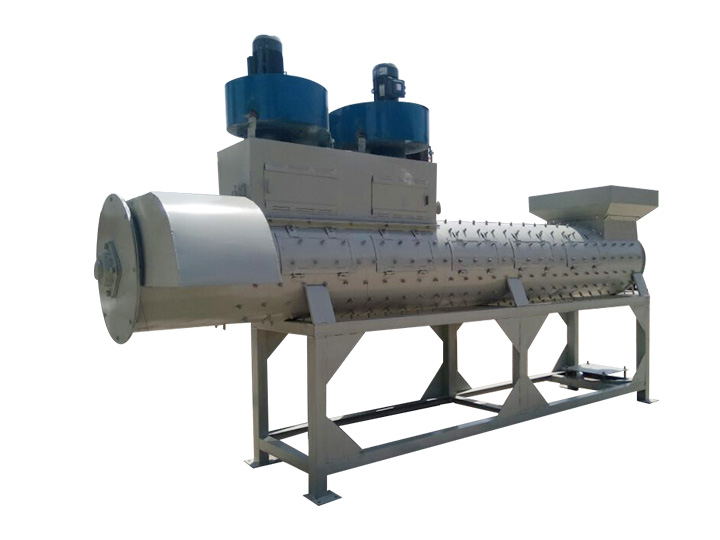

The styrofoam densifier crushes waste foam, such as foam fast food boxes, foam packaging boxes, thermal insulation materials, refrigerator outer packaging foam, and other white foaming garbage. Then they will be pushed to the heating zone by a screw, after heating and plasticizing, the plastic foam will be squeezed into a lump.

Application of the EPS foam melting machine

The styrofoam recycling machine crushes waste foam, such as foam fast food boxes, foam packaging boxes, thermal insulation materials, refrigerator outer packaging foam and other white foaming garbage. This machine is suitable for plastic recycling plants of all sizes.

Styrofoam densifier using precautions

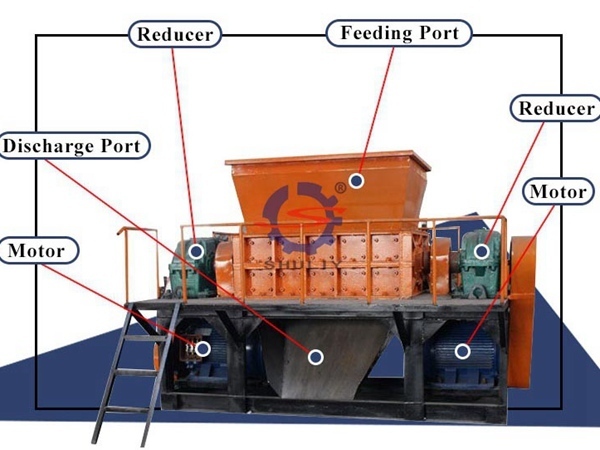

After the motor is installed, connect the three live wires. After power on. First, debug the motor forward and reverse direction. If the direction of rotation does not match, stop the styrofoam densifier, and then change the position of any two live wires.

The foam densifier is equipped with two 220V heating coils. Each heating coil has two binding posts. Any one of the live wires and a neutral wire is connected and then connected to the other heating coil in parallel. After heating for 30 minutes, the material can be turned on and fed run.

Fill up the oil before starting the densifier, add a little bit of oil every three days after use, and reinforce the screws.

Before using the foam densifier, a horizontal foam grinder can be used to achieve a coarse grinding of the raw material, making the recovery of the densifier more efficient.

Parameters of the styrofoam recycling machine

| Type | Outlook Size (mm) | Feed Port Size (mm) | Configuration Power (KW) | Inlet Power (KW) | Capacity(KG/h) |

| 220 | 1500*800*1450 | 450*600 | 15 | 3 | 100-150 |

| 880 | 1580*1300*850 | 800*600 | 18.5 | 3 | 150-200 |

| 1000 | 1900*1580*900 | 1000*700 | 22 | 3 | 200-250 |

Foam densifier melting machine video

Related Styrofoam recycling equipment

Hot Product

Plastic Sink Float Separation Washing Tank

Our plastic sink float separation washing tank uses…

Plastic shredder machine for metal tire shredding

The plastic shredder machine mainly uses the principle…

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

Waste Plastic Crusher for PP LDPE HDPE Recycling

A waste plastic crusher cuts plastic materials into…

Fibre Shearing Machine | Fiber Shredder for cutting waste cloth

The fibre shearing machine can cut worn-out clothes…

Plastic baler machine

The commercial plastic baler is mainly used for…

Vertical type dewatering machine for waste plastic films

A vertical type dewatering machine is used for…

PP PE Plastic Crushing and Washing Machine

The plastic crushing and washing machine is mainly…

Rigid plastic recycling lines for HDPE PP

The plastic recycling lines for HDPE PP and…