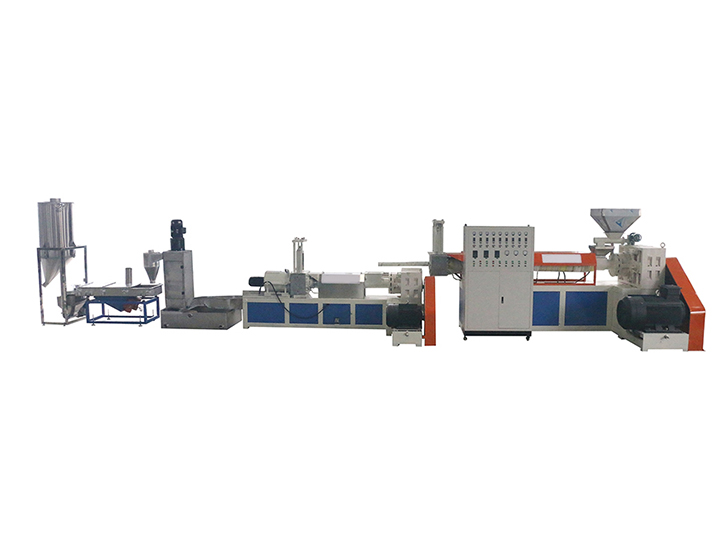

Método de instalación y uso del equipo granulador de plástico.

Instrucciones de instalación de máquinas granuladoras de plástico.

Primero, el primer método de operación de arranque.

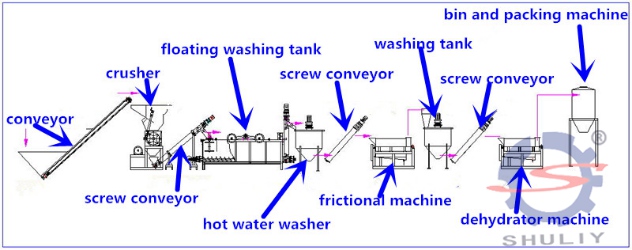

1. Antes de poner en marcha la máquina, primero calentar durante unos cuarenta y cinco minutos para subir la temperatura a la correa trapezoidal motorizada hasta que quede libre; tire de él continuamente de ocho a diez veces de acuerdo con la rotación de trabajo normal y luego continúe calentando durante unos diez minutos, luego enciéndalo, pero continúe agregando temperatura, porque la producción normal requiere una reposición continua de calor; Se ajustan diferentes temperaturas según los plásticos de diferente naturaleza.

2. Cuando el granulador de plastico está funcionando normalmente, la temperatura de la máquina debe ser estable y no debe ser alta ni baja. Cerca del orificio de ventilación, hasta que la temperatura de la nariz sea de aproximadamente 200 °C (consulte el material de propileno).

3, la alimentación debe ser uniforme y agregar suficiente. La velocidad de alimentación de la máquina y la velocidad de alimentación deben ser apropiadas. De lo contrario, afectará la calidad y el rendimiento de las partículas.

4. Cuando se apaga la máquina granuladora de plástico, el host debe cortar completamente la energía. Se debe quitar el tapón del cabezal (con la pieza de llave). Calentar por separado antes del siguiente uso.

En segundo lugar, tenga en cuenta:

1. El granulador de plastico debe correr hacia adelante; Evite la rotación inversa.

2, las máquinas granuladoras de plástico deben evitar que la máquina fría funcione con el estómago vacío, deben ser alimentadas por la máquina principal, para evitar el fenómeno de que las barras se peguen (eje de sujeción).

3, el puerto de alimentación del granulador de plástico, está estrictamente prohibido ingresar hierro y otros desechos en el orificio de ventilación. Para evitar accidentes y afectar la producción.

En tercer lugar, precauciones del proceso de trabajo de las máquinas granuladoras de plástico.

1. Preste atención al cambio de temperatura del cuerpo en cualquier momento cuando toque la astilla con la mano limpia, debe calentarse inmediatamente. Hasta que la astilla sea normal.

2, cuando las partes del cojinete del reductor están quemadas o acompañadas de ruido, deben repararse a tiempo y reponerse.

3. Cuando las piezas del cojinete en ambos extremos de la carcasa del cojinete principal estén quemadas o hagan ruido, detenga la máquina y agregue grasa. Durante el funcionamiento normal, la cámara de rodamientos se engrasa cada 5 o 6 días.

4, preste atención para conocer las reglas de funcionamiento de la máquina; tales como: temperatura de la máquina, velocidad, velocidad, según la situación, procesamiento oportuno.

5, cuando el fuselaje está inestable, se debe verificar si el espacio entre los acoplamientos está demasiado apretado y se debe aflojar a tiempo.

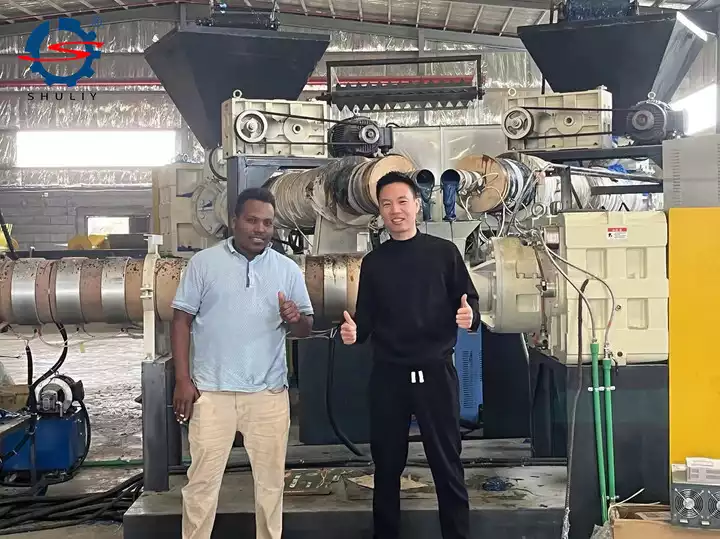

Instalación de fábrica de máquinas granuladoras de plástico en Arabia Saudita

En la industria del reciclaje de plástico, la instalación y depuración de maquinaria son pasos cruciales para garantizar una producción eficiente. Recientemente, un cliente de Arabia Saudita compró nuestras máquinas granuladoras de plástico y encontró algunos problemas a su llegada a Arabia Saudita.

Sin embargo, nuestro equipo se caracteriza por su profesionalismo y eficiencia. Enviamos un equipo de ingenieros expertos a la instalación de reciclaje de plástico en Arabia Saudita. Estos ingenieros no sólo son expertos en mecánica sino también excelentes comunicadores. Instalaron con rapidez y precisión las máquinas granuladoras de plástico, asegurándose de que todo funcionara sin problemas.

Pero eso no es todo. Nuestro equipo de ingeniería también brindó capacitación integral al personal local para garantizar que pudieran operar el granulador de manera competente. La capacitación es clave para la transferencia de tecnología y fue una parte integral de nuestra exitosa colaboración.

La instalación de la máquina granuladora de plástico en Arabia Saudita fue una colaboración perfecta, lo que demuestra nuestro compromiso de proporcionar equipos de alta calidad y soporte profesional a clientes de todo el mundo. Esperamos tener asociaciones más exitosas en el futuro, contribuyendo al desarrollo sostenible de la industria del reciclaje de plástico.

Si está interesado en maquinaria de reciclaje de plástico, no dude en contactarnos completando la ventana emergente en nuestro sitio web.