Quels sont les équipements de la ligne de granulation de la machine à granulés de plastique pour déchets ?

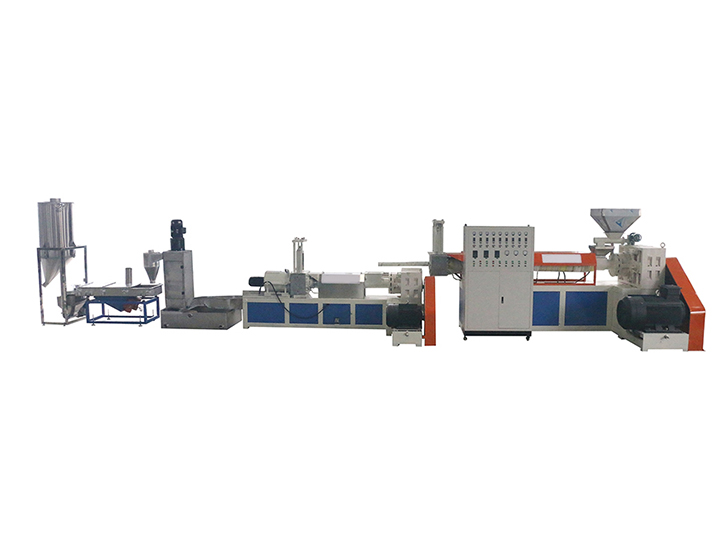

Granulateur en plastique système

Une fois la bande refroidie par le système de refroidissement, elle entre dans la machine à granulés de plastique et est roulée en granulés pour un emballage pratique. Une roue d'alimentation roulante est disposée sur le granulateur, le matériau est automatiquement transféré au corps par le moteur et la lame roulante à l'intérieur du corps est coupée.

Dissolvant de fer à nourrir

Les plastiques contiennent souvent des blocs de fer que nous ne pouvons pas retirer. Ces blocs de fer affecteront directement la production et affecteront la durée de vie du granulateur. L’invention de la machine à repasser d’alimentation en plastique résout efficacement ce problème. On peut dire que c'est du plastique. Un appareil indispensable pour les machines à granulés.

Système de chauffage

Le système de chauffage se compose de serpentins chauffants, qui sont distribués séparément à l'extérieur du baril, et les matériaux dans le baril sont uniformément chauffés et plastifiés, et contrôlés par l'instrument sur l'armoire électrique pour modifier automatiquement la température réglée.

Baril

La conception du canon adopte l'acier 45# après un traitement fin et un traitement de trempe avec une dureté élevée et une certaine résistance à l'usure et à la corrosion, et une certaine taille de fente est prévue à l'extrémité d'alimentation pour faciliter l'alimentation.

Ventilateur de refroidissement et refroidissement par eau

Afin d'obtenir la stabilité de la température à l'intérieur du baril, un ventilateur de refroidissement est ajouté au fond du baril et la température est automatiquement contrôlée lorsque la température est trop élevée, ce qui augmente la stabilité de la température du baril. Certains fabricants utilisent également la circulation de l’eau pour refroidir.

couler

Le fil tiré par le granulateur en plastique est chaud et mou et ne peut pas être granulé. La fonction de l'évier est de faire sortir le fil de plastique de l'eau, de solidifier le fil, puis de le granuler.

Matrice de machine à granulés en plastique

Afin d'empêcher l'extrusion du plastique, la température est abaissée, la fluidité est insuffisante et l'extrusion est entravée. Concrètement, un serpentin chauffant d'une certaine puissance est ajouté à l'extérieur de la tête de la machine pour assurer une décharge normale et complète. Et le trou de décharge défini sur la tête de la machine est de type parallèle à 15 trous, ce qui augmente la quantité de décharge et augmente la vitesse de production. La tête de la machine structure la tête d'extrudeuse parallèle, le fil est connecté au baril, ce qui peut économiser du temps et des efforts lors du remplacement du pochoir.

Réservoir de stockage

Avec l'amélioration continue de l'équipement et les besoins des clients, le seau de stockage de granulés de plastique entre progressivement dans l'équipement de la chaîne de production de machines à granulés de plastique, et le fonctionnement de l'équipement est simple et permet d'économiser du temps et des efforts.

Shuliy Machinery a exporté lignes de granulation du plastique vers de nombreux pays comme le Nigeria, l’Arabie Saoudite, le Kenya et la Zambie. Envoyez-nous un message pour nous contacter via le formulaire du site.