Blue HDPE Drum Recycling: A Key Step in Promoting A Circular Economy for Plastics

With the increasing threat of plastic waste to the environment, plastic recycling has become a global concern. HDPE Big Blue Drums (High-Density Polyethylene Drums) are considered to be a typical representative of recyclable plastics due to their durability, chemical stability, and wide range of applications. This article will introduce the recycling process of HDPE Big Blue Drums, its environmental significance and the use of its recycled materials.

Application of HDPE drums

HDPE blue drums (High Density Polyethylene Blue Drums) are widely used in a number of industries, mainly for storing and transporting liquid or powdery materials. They are often used as chemical raw material storage drums, food grade liquid storage drums, agricultural fertilizer drums, industrial lubricant drums, and as multi-purpose containers in logistics and warehousing due to their high strength, chemical resistance and durability.

These blue drums are also particularly suitable for scenarios requiring high liquid safety, such as the transportation of drinking water, storage of detergents and pharmaceutical products, due to their leak-proof design and environmentally friendly characteristics. The wide range of applications fully demonstrates the practicality and recyclability of the HDPE material.

What are the waste HDPE drum recycling process?

The recycling of HDPE big blue drums is mainly divided into the following steps:

Step 1: Collection and classification:

Waste HDPE drums are collected centrally by waste recyclers or enterprises. They are classified with other waste plastics by manual or mechanical means.

Step 2: Shredding:

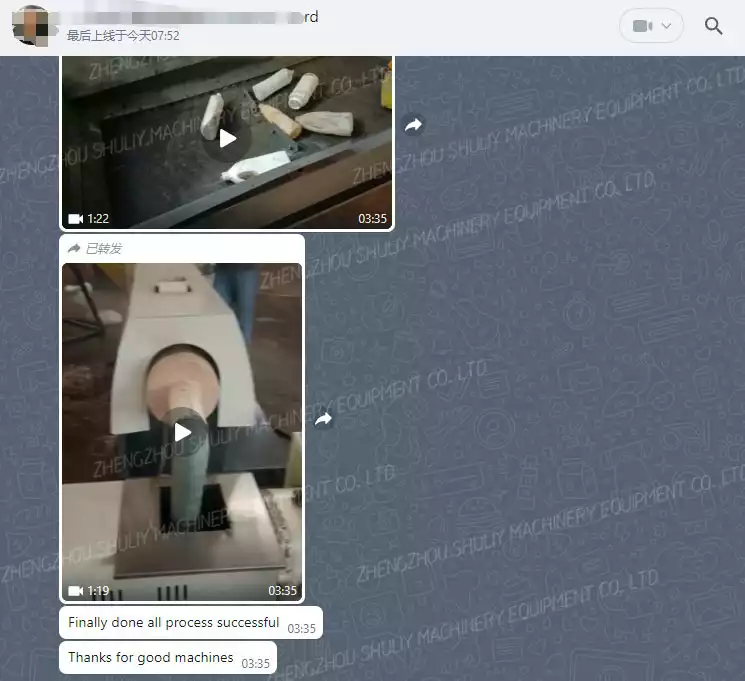

Feed HDPE drums into a plastic shredder to process them into small pieces of plastic. The crushed flakes are easy to clean and further process.

Step 3: Cleaning: Cleaning equipment is used to remove residual chemicals, oil or food residues from the HDPE pieces.

Step 4: Melt and pelletizing:

HDPE chips are fed into a HDPE pelletizer, heated at high temperatures to melt, then extruded and cut into uniform plastic pellets. These recycled pellets can be used to produce new plastic products, such as plastic drums or pipes.

How to choose your poly drum crusher?

Processing capacity (output): Determine the required shredder capacity (e.g., how many kilograms of HDPE drums per hour) based on your recycling needs.Shuliy shredders are available in a variety of models that can process 600-1200 kg of plastic per hour, which can satisfy different throughput requirements.

Blade design and material: HDPE drums are a tough material, so they need strong and wear-resistant blades. Shuliy recommends recycling plants to choose equipment with alloy steel to ensure effective cutting of the blue drums and prolonged service life.

Depending on the size and shape of the HDPE drums, Shuliy can configure a large pulverizer with a conveyor design that is suitable for handling large drums.