How Many Types of Plastic Granules Are There?

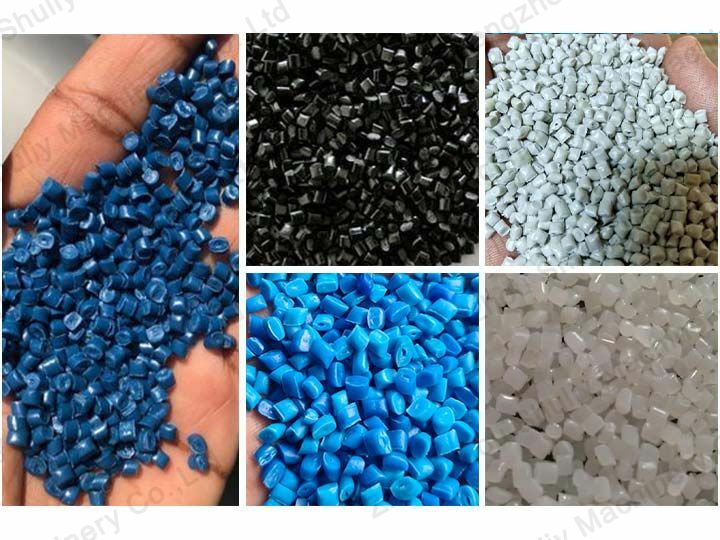

Plastic granules are a versatile and widely used material in various industries. They serve as the building blocks for manufacturing a wide range of plastic products. In this blog, we will explore how many types of plastic granules are there in the market and their specific characteristics and applications.

Plastic granules are small, uniform particles obtained by processing and transforming plastic waste. They are produced through a granulation process that involves melting, extrusion, and cooling of the plastic material. These granules act as the raw material for manufacturing plastic products.

Common Types of Plastic Granules

Polyethylene (PE) Granules:

Polyethylene is one of the most common types of plastic used in various applications. PE granules are known for their excellent flexibility, chemical resistance, and electrical insulation properties. They are widely used in the production of packaging materials, pipes, films, and containers.

Polypropylene (PP) Granules

Polypropylene granules offer high tensile strength, chemical resistance, and thermal stability. They find applications in the automotive industry for manufacturing bumpers, interior trims, and battery casings. PP granules are also used in household products, packaging materials, and textiles.

Polyvinyl Chloride (PVC) Granules

PVC granules are known for their durability, flame resistance, and excellent electrical insulation properties. They are extensively used in the construction industry for pipes, profiles, and window frames. PVC granules are also utilized in the production of flooring, cables, and automotive parts.

Polystyrene (PS) Granules

Polystyrene granules are lightweight and possess good impact resistance. They are commonly used in packaging materials, disposable cutlery, and insulation products. Expanded polystyrene (EPS) granules are utilized for packaging fragile items and as insulation in construction.How many types of plastic granules are there in the market, the above four materials are the common types.

Omani Customers Use Shuliy Granulator Producing HDPE Pellets

Specialty Plastic Granules

Acrylonitrile Butadiene Styrene (ABS) Granules

ABS granules exhibit high impact strength and excellent heat resistance. They are widely used in the automotive industry for manufacturing interior trims, dashboard components, and exterior body parts. ABS granules are also utilized in electronic appliances and consumer goods.

Polyethylene Terephthalate (PET) Granules

PET granules are transparent, lightweight, and possess excellent barrier properties. They are primarily used in the production of beverage bottles, food containers, and polyester fibers. Recycled PET granules, known as RPET, are gaining popularity due to their eco-friendly nature.

If you are interested in plastic pellets manufacturing, welcome to consult us, We provide professional plastic pelletizing machines for recycling pellets of various types.