How to avoid the carbonization of plastic pellets?

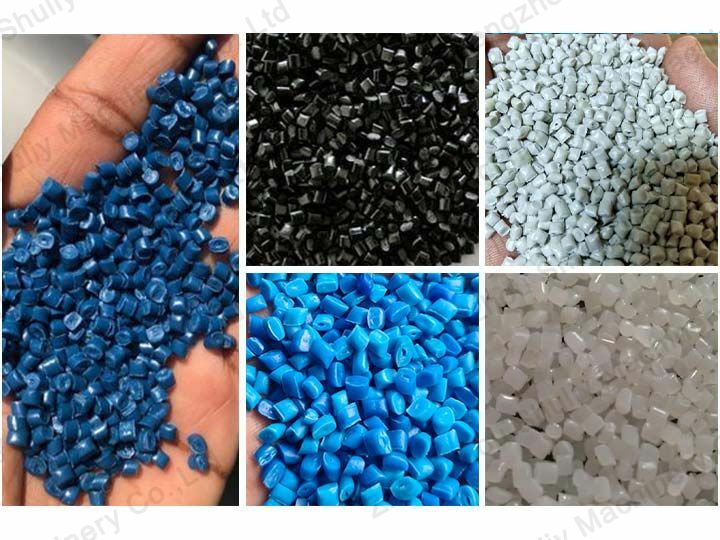

Some customers have reported that the plastic granules produced by the plastic granulator have black spots, especially on colored and light-colored products, which greatly affects the appearance. Why is this? In fact, the appearance of black spots is a common production phenomenon, which is carbonization in the pelletizing machine for plastic recycling.

Why are plastic pellets carbonized?

As the plastic melt has strong adhesion to the metal, it is impossible to completely exclude it at each shutdown, so there is always a thin layer of plastic melt firmly adhered to the barrel and headwall of the extruder and the screw, leaving a hidden problem for future carbonization.

After shutdown, the equipment is still at high temperature and then left to be heated next time, the residual plastic stays in high temperature for a long time, and gradually becomes yellow and charred to become carbide.

According to the conventional shutdown method, no effective sealing measures are taken at both ends of the die opening and feed opening of the machine head, resulting in the air entering the machine to produce oxidation, which provides favorable conditions for carbonization.

Methods to avoid carbonization

When encountering this situation, the staff should quickly clean up the carbide in the pelletizing machine for plastic recycling. For the general plastic pellet machine, you can use harder plastic or add white mineral oil to clean, and the temperature should be increased by 10~15°C.

For large and medium-sized extruders that can plasticize UHMW plastic, you can use UHMW plastic or its return material with white mineral oil to clean. Because the hardness of ultra-high molecular weight plastic is better, coupled with the higher temperature, the cleaning object will be softened, thus becoming easy to fall off, which is conducive to the carbide is brought out by the plastic melt.

During the cleaning process, the speed of the plastic extruder machine is repeatedly switched between low speed and high-speed several times. The machine can be repeatedly stopped and restarted several times during the operation in order to further improve the cleaning effect.

When the black spot in the melt is obviously reduced, replace the usual plastic cleaning until clean, gradually adjust to the appropriate temperature, then you can normal production.