小型プラスチック造粒機の使用方法と注意事項

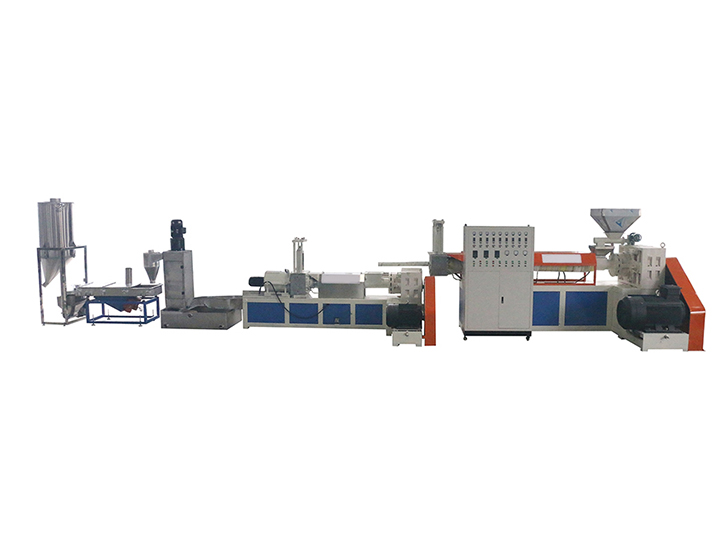

廃プラスチックをリサイクルするための市販のプラスチックペレタイザーは、現在市場で非常に人気のある製品です。廃プラスチックのリサイクルには、 プラスチックリサイクル生産ラインの完全なセット または製造にはプラスチック造粒機のみを使用します。最近では多くの製品を輸出しています 小型プラスチック造粒機 多くのアフリカ諸国のユーザーに。ここでは小型プラスチック造粒機の使用方法や注意点を中心に紹介します。

プラスチック造粒機の操作方法

1. プラスチック造粒機を使用する前に、装置を予熱し、約 40 分間加熱します。モーターの V ベルトを手で引っ張って快適になるまで温度を上げます。通常の作業方向に 8 ~ 10 回連続して引っ張ります。その後、約 10 分間加熱し続けます。その後、電源を入れますが、通常の生産では熱を加え続ける必要があるため、加熱を続けます。ユーザーは、異なるプラスチックに応じて異なる温度を設定および調整する必要があります。

2.小型プラスチック造粒機が正常に動作しているとき、機械の温度は安定に保たれ、変動があってはなりません。ミシン頭部の温度は200℃程度に保ってください。

3. プラスチック造粒機を使用する場合、供給量は均一である必要があります。機械の処理速度と供給速度が適切に一致していなければ、プラスチック粒子の品質と生産量に影響を及ぼします。シャットダウンするときは、ホストは電源を完全に遮断する必要があります。ミシン頭部のネジプラグ(レンチが付いている部分)を外す必要があります。次回使用する前に別途予熱してください。

市販のプラスチック製造粒機の使用上の注意

1. プラスチック造粒機を運転する際は、清浄度、粘度などの条件を満たす作動油を使用し、油による油圧機器やパイプラインの詰まりや漏れを防ぐために、必要に応じてオイルクーラーに十分な冷却水を供給してください。汚れや高温。油のような現象。また、プラスチック造粒機の減速機には、要件を満たす潤滑剤を充填する必要があります。

2. プラスチック造粒機は、運用規則の要件に従って厳密に運用されなければならず、非稼動ステーションでは違法な運用を行ってはなりません。安全装置の信頼性を確保するには、効率を追求するあまり機械の安全保護対策を破壊してはなりません。

3. プラスチック造粒機の運転中に、温度が設定温度に達しておらず、保持時間が十分でない場合、スクリューは始動できません。操作はプラスチック造粒機の構造、性能、操作方法を熟知した訓練を受けたオペレーターが行います。