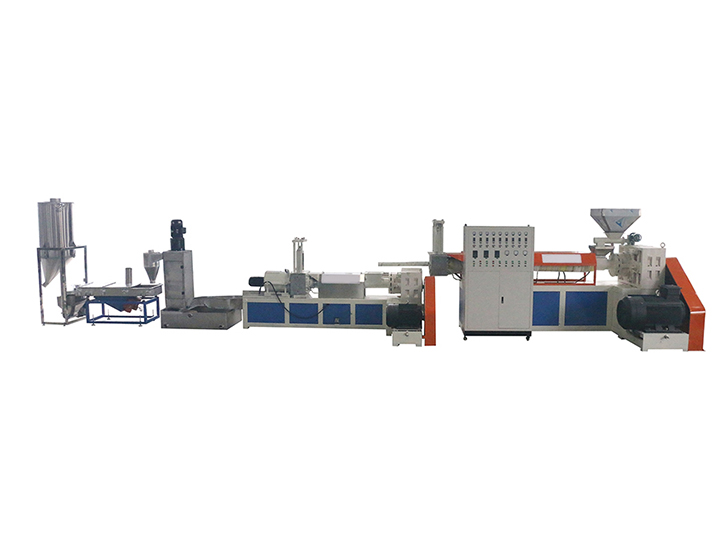

廃プラスチックペレット機械の生産作業では、次の点に注意する必要があります。

1. 火災安全のため、熱媒体油を使用する機器の近くに消火器を設置する必要があります。

2. 故障または異常事態が発生した場合は、関係者に報告し、山の専門保守員が対応する必要があります。安全に影響を与える異常現象が発生した場合は、直ちに非常停止スイッチを押してください。

3. 金属不純物や沈殿物を含む粗悪な材料は使用しないでください。スクリューやバレルの磨耗、詰まり、損傷を防ぐため、供給ポートの近くに落下する可能性のある金属物を置かないでください。

4、プラスチックペレット機械の操作では、オイルの汚染や高温による油圧コンポーネントやパイプラインを避けるために、必要な作動油と一致する清浄度、粘度、その他の指標を使用し、オイルクーラーに十分な冷却水の流れを提供する必要があります。 -温度詰まり、油漏れ、その他の損傷。押出機には必要な潤滑剤を充填する必要があります。

廃プラスチックペレット機械の生産作業では、次の点に注意する必要があります。

5. プラスチックペレット製造機を操作するときは、操作手順の要件に厳密に従わなければならず、非操作ステーションで違法な操作を実行することは許可されません。安全装置の信頼性を確保するには、プラスチックペレット製造機の安全保護手段を破壊して効率を高める必要があります。

6. プラスチック造粒機の製造では、オペレーターはプラスチック機械構造の性能と操作手順に精通している必要があります。

7. プラスチック機械を運転する際、材料温度が設定温度に達せず、保持時間が不十分な場合、スクリューを回すことができません。

廃棄物の正しい処理 プラスチック造粒機 機器の耐用年数を延ばすことができるという利点があります。しかし、プラスチック造粒機の使用は私たちの日常生活では十分に注目されておらず、不要な問題も引き起こしているため、プラスチック機械を使用する際にはこれらの問題に注意してください。皆さんもぜひメッセージを残してください。