Laminated film recycling

Laminated films are composite materials made by bonding together two or more layers of different materials, such as plastic, paper, or metal, using adhesives or heat. This process enhances the properties of the individual layers, resulting in a versatile material widely used in various industries. Laminated films offer improved functionality, durability, and aesthetic appeal, making them essential in modern packaging and manufacturing.

Laminated film application

Laminated films are used across a wide range of industries, thanks to their versatile properties. Some of the key applications include:

Food Packaging: Laminated films are extensively used in food packaging due to their superior barrier properties. They help extend the shelf life of perishable goods, protect against contamination, and preserve flavors and aromas. Common uses include snack packaging, vacuum-sealed pouches, and ready-to-eat meal packaging.

Pharmaceutical Packaging: In the pharmaceutical industry, laminated films provide the necessary protection against moisture, light, and air, ensuring the stability and efficacy of medications. They are used in blister packs, sachets, and strip packs for tablets, capsules, and powders.

Industrial application: Laminated films are also used in industrial applications such as insulation, protective coverings, and wrapping materials. Their strength and resistance to environmental factors make them suitable for protecting products during storage and transportation.

Laminated film can be recycled

The laminated film includes HDPE, LDPE, LLPDE, BOPP, CPP, OPP, or EVA. When it comes to food (especially puffed food), and candy packaging, those plastic packing bags always include a metalized layer. Laminated films can be recycled.

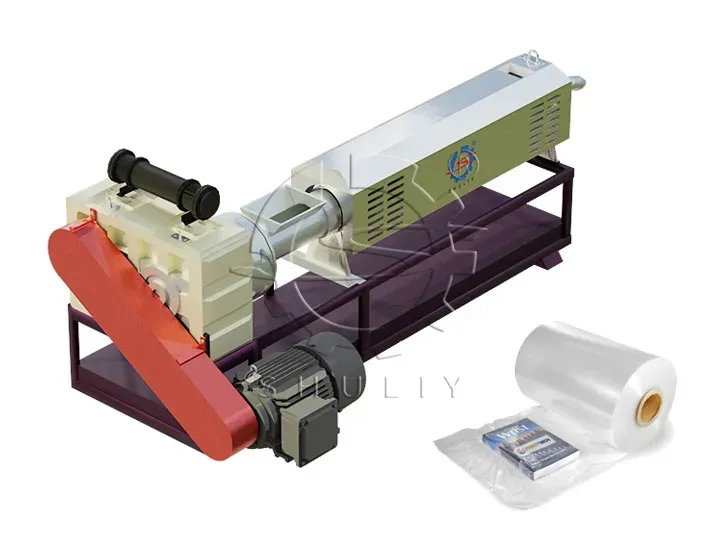

Recycling machines designed for laminated film

Shuliy’s highly efficient plastics recycling lines and associated configurations are designed for reprocessing laminated film scrap. Compared to regular PE film, composite moldings are more difficult to cut because of their high tensile strength.

Our newly designed plastic shredders have been specifically modified and enhanced for this purpose, and the high-quality pellets made from the laminated material allow producers to reuse them in production lines for injection molding, thermoforming, extrusion or other applications.

Shuliy pelletizer screws for laminated films are carefully designed to efficiently process various materials, including laminated, metallized and fully printed film scrap. This creative design allows the pelletizer screw to gently process the recycled material without causing plastic denaturation or degradation, ensuring the production of high quality plastic pellets.