Something You Should Know About the Medical Plastic Recycling

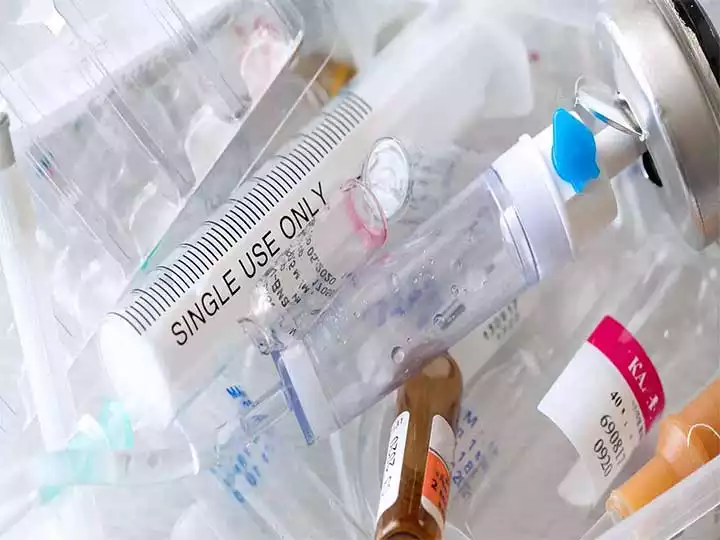

With the rapid growth of the healthcare industry, the use of medical plastic products is increasing. From disposable syringes to medicine bottles, medical plastic products play a vital role in healthcare. However, how to properly dispose of and recycle these plastic products is an important issue that requires attention. Below we explore common medical plastic products and medical plastic recycling methods.

What are the common medical products?

- Disposable syringes: they are usually made of polypropylene (PP) and polyethylene (PE), which are characterized by high temperature and chemical resistance.

- Pharmaceutical bottles: most medicine bottles like prescription bottles and pill bottles are made of high-density polyethylene (HDPE) or polyethylene terephthalate (PET), they are used to package liquid or solid medications.

- Intravenous infusion bags: They are usually made of polyvinyl chloride (PVC) or ethylene vinyl acetate (EVA), which have good transparency and elasticity.

- Surgical Gloves: Surgical gloves are mainly made of polyethylene or latex and are used to prevent cross-contamination.

- Plastic medical tubing: Commonly used for catheters, breathing tubes, etc., usually made of PVC or silicone materials.

Are the above medical plastics recyclable?

While many medical plastics can be recycled, the process of recycling these plastic products must be done with great care as they may have come into contact with sick people or hazardous substances during their use. Medical plastic waste that is not properly disposed of may pose a threat to the environment and public health.

Types of medical plastics that can be recycled:

- HDPE (High Density Polyethylene): commonly used for medicine bottles, detergent containers, etc. It is easy to recycle and reprocess.

- PET (polyethylene terephthalate): used to make infusion bottles, pharmaceutical packaging, can be effectively recycled and applied to other plastic products.

- PP (polypropylene): used for disposable syringes, medical containers, etc., can be recycled and used for reprocessing of industrial products.

Challenges of medical plastic recycling

Contamination problem: The medical plastic recycling has several difficulties. Medical products are often contaminated with blood, body fluids or drug residues, so they must be thoroughly sterilized and sorted before recycling. This requires the use of specialized cleaning equipment and sterilization techniques to ensure the safety of the recycling process.

Complexity issues: Some medical plastics are made from a variety of different plastic materials, which complicates the recycling process. For example, IV bags may contain PVC, rubber and metal components, requiring the different materials to be handled separately.

How to do the medical plastic recycling?

Sorting and Sterilizing: All medical plastic waste needs to be carefully sorted before recycling to ensure that different types of plastics can be handled separately. At the same time, contaminated plastic products must be sterilized before recycling to ensure that they do not spread germs or viruses.

Mechanical plastic recycling method: Mechanical plastic recycling is by far the most common method of recycling medical plastics. It needs some professional plastic recycling equipment like shredding machines, cleaning machines, granulators and plastic dryers. Plastic waste is first crushed into small pieces by a medical plastic scrap shredder, then washed and melted to be reprocessed into plastic pellets by a pelletizing machine. These pellets can then be reused to make other plastic products.

Read more:

Complete recycling solutions & lines for rigid plastic

Soft materials like plastic film & bags reprocessing solution & machinery

Energy Recovery: Energy recovery is another option when certain plastic scraps are difficult to recycle. By burning plastic waste, the thermal energy released can be used to generate electricity or heat, thus reducing the environmental impact of the waste.