How is price of Netherlands EPS foam recycling machine?

EPS foam recycling machines could crush, melt, cut, and granulate waste EPS plastic materials. The processed EPS plastic particles could apply to packaging and insulation materials. Since our plastic recycling machines have been sold to many countries, we have also learned about the market for recycling machines in some countries. This post is about the Netherlands EPS foam recycling machine cost.

A brief introduction to Netherlands EPS foam recycling machine

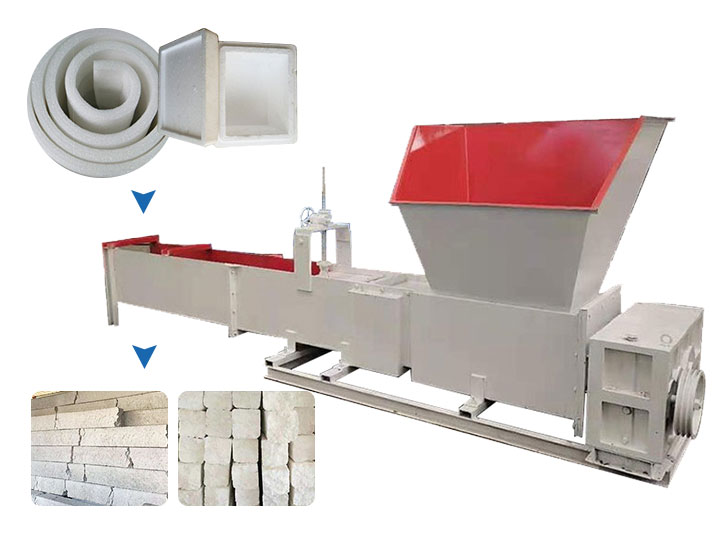

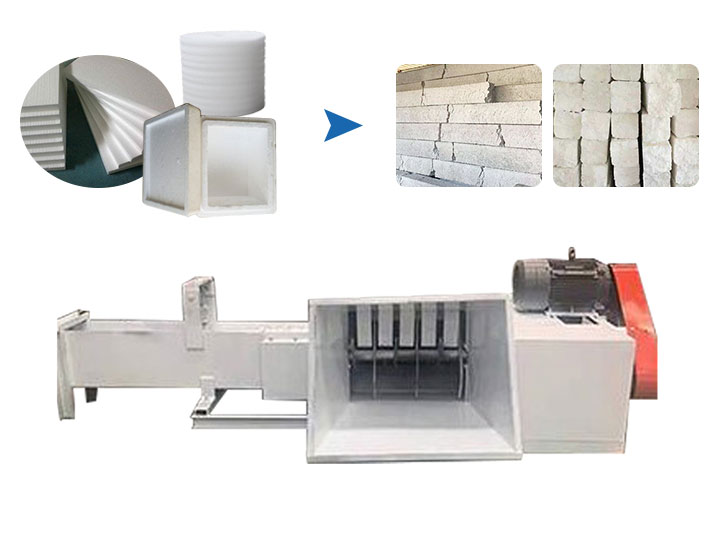

The EPS foam board recycling machine is a mechanical environmental protection equipment that crushes foam plastics according to the principle of spiral rotation and pressure and performs cold compression and compression treatment on them. When in use, the operator only needs to put the foam into the hopper, and the foam is broken by the screw cutter of the equipment, and the broken foam processed by the screw cutter will enter the screw and squeeze the foam into a block by the hydraulic device.

Due to the large volume, lightweight, inconvenient transportation, and high storage cost of EPS waste foam, foam recycling equipment is widely used to process a large amount of foam waste, which not only greatly increases the foam density for secondary recycling and granulation, but also greatly reduces landfilling. Pollution. For this reason, Inco Environmental Machinery has developed the environmentally friendly GREENMAX foam recovery machine Apolo-c100 equipment with no secondary pollution.

Application and Scope of application

This Netherlands EPS foam recycling equipment is mainly used for waste paper processing, including paper, EPS (polystyrene foam), XPS, EPP, etc. The materials are crushed by a shredder and then compacted into blocks. The handling of solid materials with this device is not allowed. The manufacturer will not bear any responsibility if any losses are caused due to errors in the operation.

Advantage of Netherlands EPS foam recycling machine

This equipment is used for compressed waste treatment, including paper, EPS, XPS, EPP, etc. So this machine can reduce EPS etc.

For environmental pollution, protect the environment. At the same time, the machine can reduce storage and transportation costs by compressing materials such as EPS.

This makes the recovery of EPS etc. easier and more convenient. In short, this machine has great advantages in terms of energy and environment.

Factors affecting the cost of EPS foam recycling machine in the Netherlands

- Capacity

We could provide EPS foam recycling machines with different outputs.

- Recycling demands

There are various plastic recycling machines, including EPS foam recycling lines, EPS foam granulators, EPS foam compactor, and others.

- Raw materials

Since there are EPS, EPE, PE, PP, and other types of plastic raw materials. And we have different recycling machines. Like EPS foam granulating line, PP PE flake pelletizing line.