Paraffin wax granule machine | Industrial paraffin pelletizer

Paraffin wax granule machine | Industrial paraffin pelletizer

The paraffin wax granule machine utilizes the low melting point characteristics of paraffin wax and other materials. After the paraffin is melted, a special distributing device sprays the molten liquid evenly on a moving steel belt below. At the same time, under the steel belt, there is a continuous cooling device, which enables paraffin wax particles to cool and solidify.

Raw materials of the wax granule machine

The paraffin pelletizer is suitable for all kinds of materials whose melting point is within 250°C and needs to be condensed and granulated. For example, typical application materials include sulfur, paraffin, rosin resin, petroleum resin, asphalt, hot melt adhesive for bookbinding, wood edge hot melt adhesive, packaging hot melt adhesive, cable sealing hot melt adhesive, etc.

Paraffin wax granule machine structures

The machine is mainly composed of a granulation forming head, cooling conveyor stainless steel belt and pulley, spray cooling system, transmission system, heat preservation device, frame, scraper, etc.

The granulation head is mainly composed of a head die sleeve and head mandrel. The spray cooling system is mainly composed of sprinklers and water tanks. The transmission system is mainly composed of a gearbox, a speed regulating motor, etc.

Advantages of the paraffin pelletizer

- Paraffin wax granule machine is of high yield rate. Generally, the yield rate is above 85%, and some materials can be close to 100%. Therefore, a steel belt type condensation granulator is much more suitable for manufacturers than the traditional pressure cooling granulation.

- The wax granule machine has high material recovery rate. Due to the high rate of finished products, the defective products have only a few small particles, which are easy to recover. Not only saves raw materials for manufacturers, but also saves recycling costs.

- The pelletizer fully meets the requirements of environmental protection. Almost all materials can be recycled, and the dust emission is almost zero.

- The paraffin wax granules are not easy to stick to the wall. The conventional cooling granulation always has a part of the sticking to the wall. The atomization disk of this equipment is specially treated, and only a small centrifugal force is required, and the material after centrifugation cannot be thrown on the wall.

- The particle size can be selected. When choosing the size, choose different centrifugal atomizers and adopt appropriate process parameters. The particle diameter can be as large as a few millimeters and as small as 200 mesh.

Operation requirements

- When operating the machine, the materials must be filtered, and solid impurities must not enter the granulation head, otherwise it will cause the head to block and affect the quality of the granulation.

- The temperature control should be based on the melting point temperature of the raw material. The temperature change should not exceed ±3℃ during heat preservation.

- The cooling system should be equipped with a filter. The cooling water temperature is generally between 5°C and 25°C. The low water temperature is helpful for rapid prototyping of the paraffin granules, so that the paraffin granules produced will be of good shape and high output.

Paraffin wax granule machine parameters

| Model | HS-W40 | HS-W60 | HS-W120 | HS-W150 |

| Machine width | 600mm | 600mm | 1200MM | 15000MM |

| Machine length | 7000mm | 12000mm | 15000mm | 23000mm |

| Size of mold | 1.8-2.2mm | 1.8-2.2 mm | 1.8-2.2mm | 1.8-2.2mm |

| Size of products | 4-8mm(adjust) | 4-8mm(adjust) | 4-8mm(adjust) | 4-8mm(adjust) |

| Products shape | hemispherical | hemispherical | hemispherical | hemispherical |

| Capacity | 50-100kg/hour for paraffin | 150-200kg/hour for paraffin | 400kg/h for paraffin | 600kg for paraffin |

| 100-200kg/hour for resin | 200-300kg/hour for resin | 600-800kg/h for resin | 800-1200kg/h for resin | |

| 100-200kg for RD | 200-300kg for RD | 600-800kg/h for RD | 800-1200kg/h for RD | |

| Motor | 5kw+1.5kw | 5kw+1.5kw | 5.5+1.5kw | 5.5+1.5kw |

| Voltage | 110v/220v/380v | 380V,50HZ,3 phase | 380V,50HZ,3 phase | 380V,50HZ,3 phase |

| Water pump | pressure: 0.3mpa waterflow: 15-20 m3/h (equipped by user) | pressure: 0.3mpa waterflow: 15-20 m3/h (equipped by user) | pressure: 0.4mpa water flow: 30 m3/h (equipped by user) | pressure: 0.4mpa water flow: 30 m3/h (equipped by user) |

For more machines, please check our site: https://www.recycle-plant.com/

Hot Product

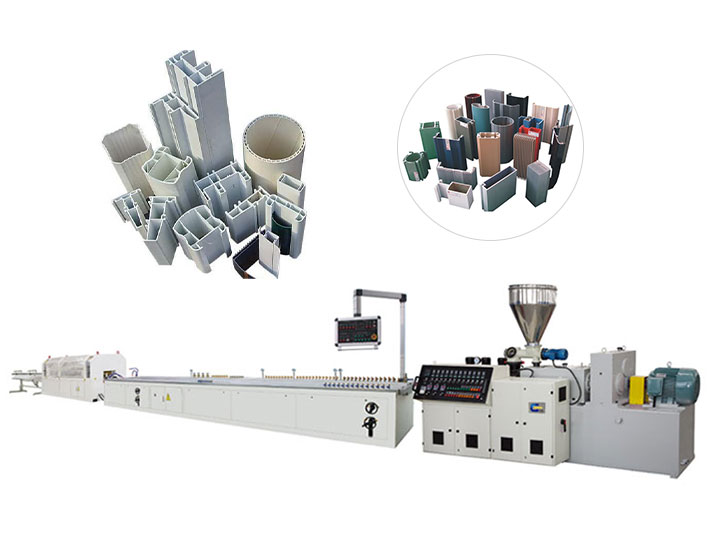

Plastic profile extrusion line | PVC ceiling making machine

Shuliy plastic profile extrustion line is a professional…

Cotton Waste Recycling Machine | Garment Rags Tearing Machine

The cotton waste recycling machine is mainly used…

Waste tire recycling line | rubber granules making machine

The waste tire recycling line uses advanced tire…

Belt conveyor | Plastic bottle sorting table

Structure of belt conveyor The belt sorting table…

Plastic Sink Float Separation Washing Tank

Our plastic sink float separation washing tank uses…

Plastic pellet bagging machine | Packing machine

Waste plastic needs to be packaged completely after being processed…

Pioneering waste plastic water ring pelletizer

Due to the advantages of the water ring…

Belt climbing conveyor | Inclined transport machine

A belt climbing conveyor is an essential machine…

Plastic Film Granulator for PP PE LDPE LLDPE Recycle

The plastic film granulator by Shuliy is a…