Plastic pellet cutting machine | Plastic granule cutter

Plastic pellet cutting machine | Plastic granule cutter

Features at a Glance

This plastic pellet cutting machine is the last step in the plastic recycling line. It has superior performance and reasonable structure, and the plastic granulator blades used are made of high-quality steel. The sealing performance of the whole machine is better, with less leakage, and It is convenient to adjust the cutting distance. the rotary cutter is made of a hard alloy hob, its wear resistance is extremely high, the plastic granule cutter without a gear design effectively reduces the machine noise with the belt rotation. and the independent electrical box is convenient, safe, and beautiful. Cold-drawn pelletizing for various high-yield, high-strength engineering plastics.

The scope of use of plastic pellet cutting machine

Plastic cutting machine, suitable for plastic blending granulation, pelletizing after plastic extrusion stripping, suitable for pelletizing plastics such as nylon, polyethylene, ABS, polypropylene, etc. It is an accessory product of plastic granulator and extruder.

It is widely used in the cutting of various plastic cold-drawn strips during plastic pelletizing process. It is suitable for PC, PA, PP, PVC, POM.PET nylon, polyethylene, ABS, polypropylene, and other plastics. Low noise and no spattering of pellets.

Structural composition of plastic granule cutter

The hob cutter is mainly composed of a feed inlet, a pressure roller, a rotary cutter, a motor, a body, and a discharge outlet. There is no gear structure in the machine, and there is no belt movement in the machine, so the running noise is small. The cutter is well heat treated to achieve the reasonable hardness and can cut materials for a long time without wear.

This machine consists of two upper rollers and one lower roller. The upper roller has two materials: rubber roller and an iron roller. The lower roller only has an iron roller. Generally, the life of the rubber roller is short, but it will not break the formed plastic strip.

Plastic cutting machine features

All transmission gears of this machine are driven by involute helical gears. The gear materials are made of high-quality steel, so the transmission is stable, the noise is low, the transmission coincidence coefficient, the bearing capacity is strong, and the service life is long.

The granules cutter machine adopts high-quality integral cutters with sharp and wear-resistant, easy installation and uniform and full cutting particles. Constant pressure traction brace, special wear-resistant polyurethane rubber roller, manual spring adjustment, traction to ensure the plastic shape of various plastic products.

The granules cutting machine is exquisite and beautiful, the structure is reasonable, the service life is long, the economy is practical, the pelletizing is uniform, the installation is convenient, and the price is economical.

How does the plastic pellet cutter work?

The plastic cutting machine is an important part of the plastic film recycling line. The process of the entire plastic pellets recycling production line is crushing-cleaning-drying-melting-cooling-pelletizing-storage. The recycling of some plastic materials does not require a cleaning step, but all require cutting. So how does the plastic pellet cutter work?

- The material is melted in the plastic pellet machine (dana machine), and after extrusion of the die head, it becomes a hot, unsettled plastic strip.

- After that, it enters the cooling tank and becomes a hard strip under the cooling of water.

- Then it is fed into the plastic particle cutter, and the pressing roller tightly fixes the plastic strip and feeds it into the continuously rotating cutter part.

- The cutter cuts the plastic strip into small particles with a smooth section and regular shape.

Features of plastic granule cutter

- The particle shape is regular, the cut surface is smoother, and the size is uniform.

- It has a wide range of applications and can be used for pelletizing materials such as PC, PET, ABS, PP, PE, PVC, and POM.

- The cutter distance is between 160mm-300mm, the length of the pellet can be adjusted and the adjustment method is simple.

- There is no gear inside the machine, and the running noise is low.

- The cutter is treated with a special process and is durable.

Plastic pellet cutting machine video

Parameter of plastic pellet cutting machine

| Model | Rotate blade number | Power | Capacity | Dimension |

| GD-140 | 18 tooth | 2.2KW | 150KG | 800*560*1150 |

| GD-160 | 18 tooth | 2.2KW | 180KG | 800*560*1150 |

| GD-180 | 22 tooth | 3.0KW | 250KG | 800*560*1150 |

| GD-200 | 22 tooth | 3.0KW | 280KG | 800*560*1150 |

Hot Product

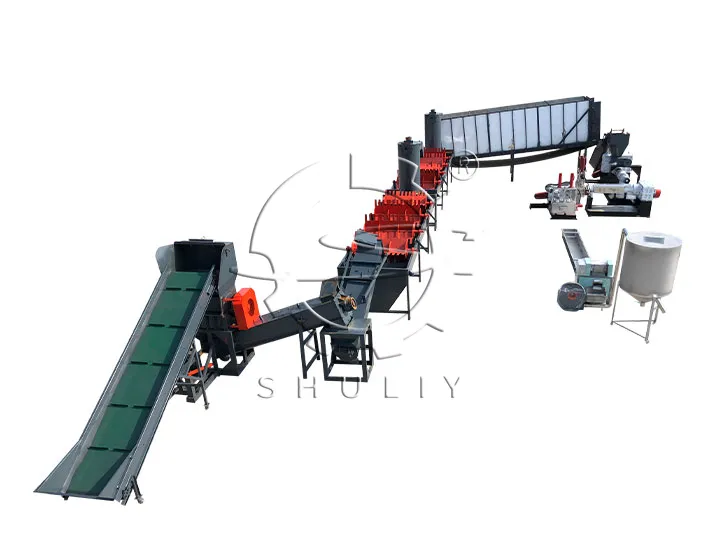

Rigid plastic recycling lines for HDPE PP

The plastic recycling lines for HDPE PP and…

Horizontal Styrofoam Shredder

A horizontal styrofoam shredder is mainly used to…

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

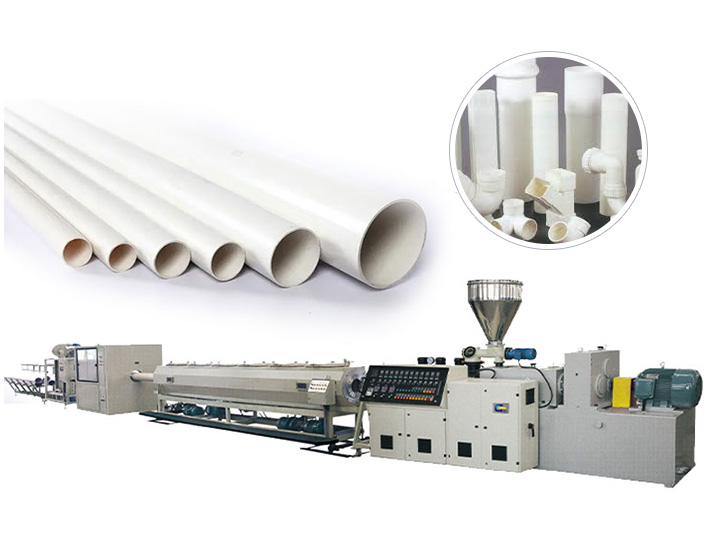

Plastic pipe making machine | PPR HDPE PVC pipe production line

Our company has a full range of plastic…

Plastic Pelletizing Machine

The plastic film pelletizing machine can also be…

Plastic pellet bagging machine | Packing machine

Waste plastic needs to be packaged completely after being processed…

Electrostatic spray machine | Manual powder coating gun

The electrostatic spray machine is industrial equipment for…

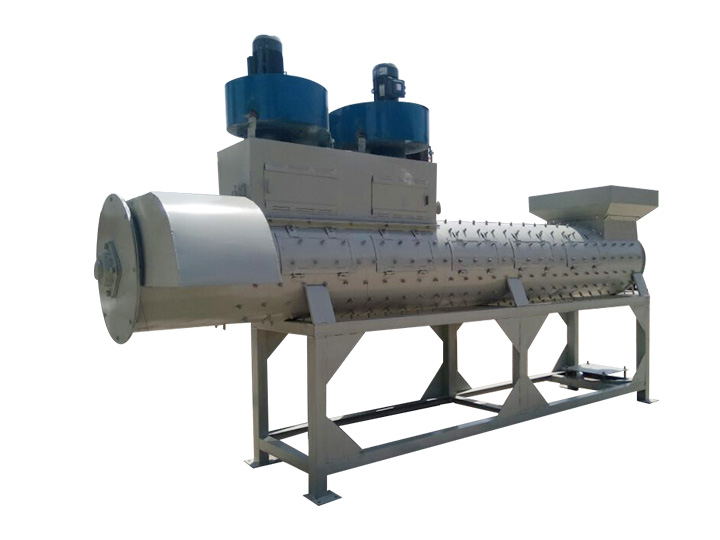

PET bottle flakes hot water washing tank

The hot water washing tank is suitable for…

Vertical foam cutting machine

The Vertical foam cutting machine is dedicated to…