PET bottle label remover recycling machine

PET bottle label remover recycling machine

Features at a Glance

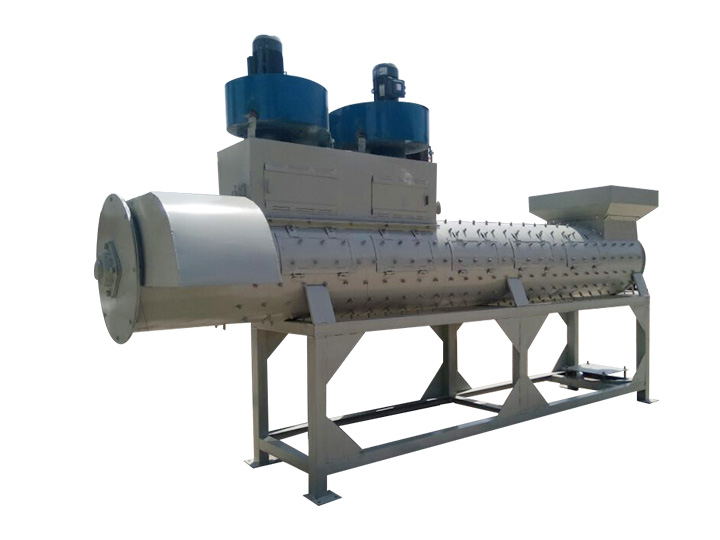

PET bottle label remover is indispensable for plastic bottle recycling and is professional in removing PET bottle labels or water bottle labels, a PET recycling machine can instead of people removing the label during the plastic bottle recycling, meeting the big capacity requirements of the production line. It can improve the efficiency of the PET bottle recycling line.

Main applications of PET bottle label removing machine

Instead of removing plastic bottle labels by labor, the PET bottle de-labeling machine can separate the PVC label and bottle body, greatly improving work efficiency and replacing manual production. It is the prelude to work before the crushing of PET bottle recycling production line. Then finally, the PET recycling machine can reduce the PVC content of PET net flakes for plastic recycling.

Working principle of the PET label removing machine

After the beverage bottle is put into the hopper, the alloy steel cutter in the de-labeling machine will cut a mouth on the trademark on the bottle. When the blade welded on the main shaft has a certain angle with the centerline of the main shaft and the spiral line rotates, the waste bottles will be conveyed to the discharge port, the toothed knife on the blade peels off the label, and then uses wind energy to separate it, which conforms to the modern environmental protection function. After the label paper is peeled off, the bottle body and the label can be automatically separated. Then the label-free plastic bottle will be sent into plastic crushers for further process.

Features of PET bottle label remover

- The PET bottle label remover can save labor with high efficiency, the working rate is about 98%.

- The machine has a large capacity.

- This PET recycling machine has more than 300 pcs special design blades, the material of blades are alloy steel, it is durable.

- By adjusting the blades, it can use for removing different size bottles in plastic bottle recycling.

How to operate PET bottle label remover?

- Start the PET recycling machine first, open the fan motor, then the main machine motor, open the conveyor motor at last.

- Please pay attention to ensure no iron or stone drops into the machine when it working, if it happens, please stop the machine at once.

- When finishing working, please close the conveyor motor first, then the main machine motor, close the fan’s motor last.

Data of PET bottle recycling machine

| Model | SL-600 |

| Main power of machine | 11kw |

| Power of fans | 3kw |

| Capacity | 1-1.2t/h |

| Rate of removing the label | 98% |

| Size | 4000*1800*1600mm |

| Weight | 1500kg |

PET bottle label remover video

Plastic bottle label removal machine exported to Nigeria

This is one of our customers in Nigeria, he purchased our PET bottle label remover machine one year and found the machine can run very well.

Inquiry of PET bottle label remover

That’s all the introduction of the PET bottle de-labeling machine, if you are interested in plastic recycling, PET bottle recycling machine and label remover, welcome to consult via Whatsapp/Wechat/Tel: +8619139754732, you can also leave a comment below the page, you will get personalized service and the price.

Hot Product

Rigid Plastic Shredder Machine

Shuliy rigid plastic shredder machine is also called…

Vertical type dewatering machine for waste plastic films

A vertical type dewatering machine is used for…

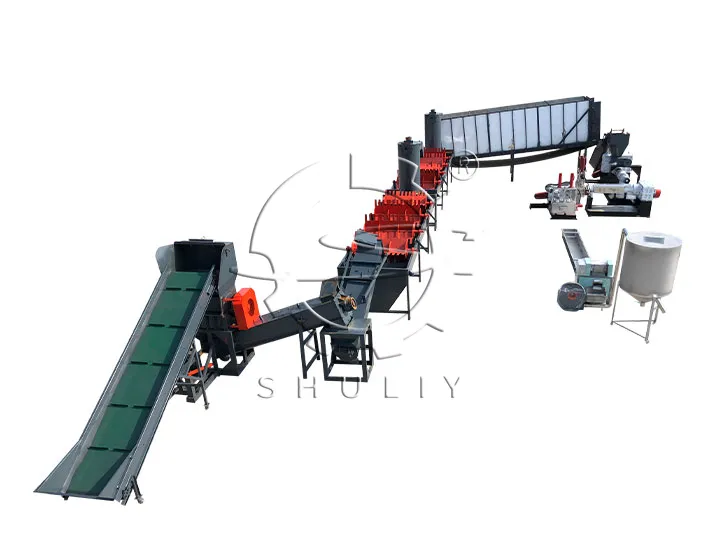

PET Plastic Bottle Recycling Machine

Our complete PET bottle recycling line is an…

Rigid plastic recycling lines for HDPE PP

The plastic recycling lines for HDPE PP and…

Electrostatic spray machine | Manual powder coating gun

The electrostatic spray machine is industrial equipment for…

Cotton Waste Recycling Machine | Garment Rags Tearing Machine

The cotton waste recycling machine is mainly used…

Plastic pellet cutting machine | Plastic granule cutter

This plastic pellet cutting machine is the last…

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

EPE Recycling Machine for Foam Pelletizing

Waste EPE foam pelletizing machine is suitable for…