Plastic Film Granulator for PP PE LDPE LLDPE Recycle

Plastic film pelletizing machine for pp raffia bag/ cement bag/woven bags | PP PE film granulator

Plastic Film Granulator for PP PE LDPE LLDPE Recycle

Plastic film pelletizing machine for pp raffia bag/ cement bag/woven bags | PP PE film granulator

Features at a Glance

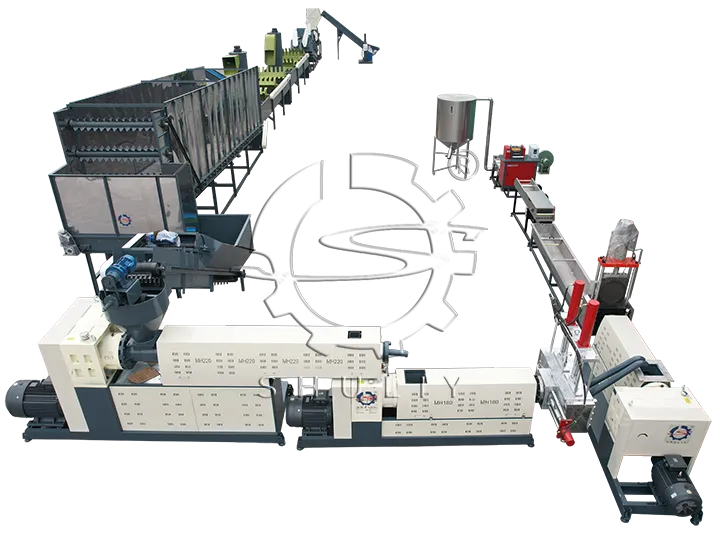

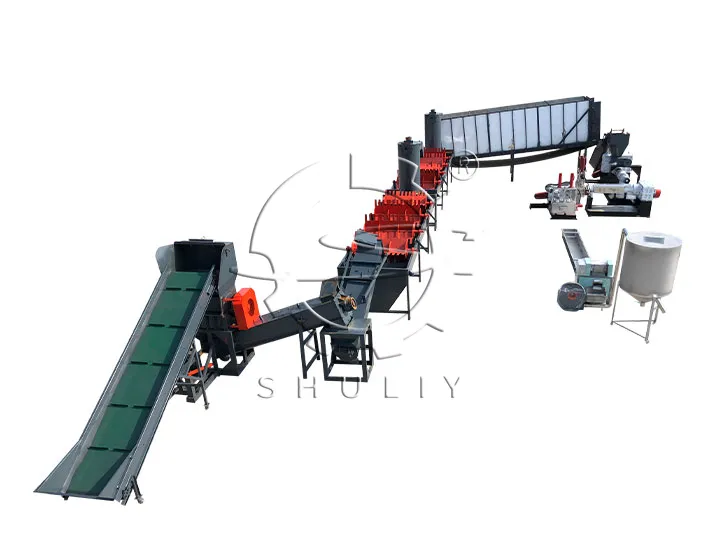

The plastic film granulator by Shuliy is a popular recycling machine designed for recycling polyethylene film, polypropylene film, waste plastic packing bags and agricultural films. With its advanced technology and robust construction, the plastic film pelletizing machine offers an efficient solution for converting plastic waste into high-quality recycled plastic pellets.

Working Principle of plastic film granulator

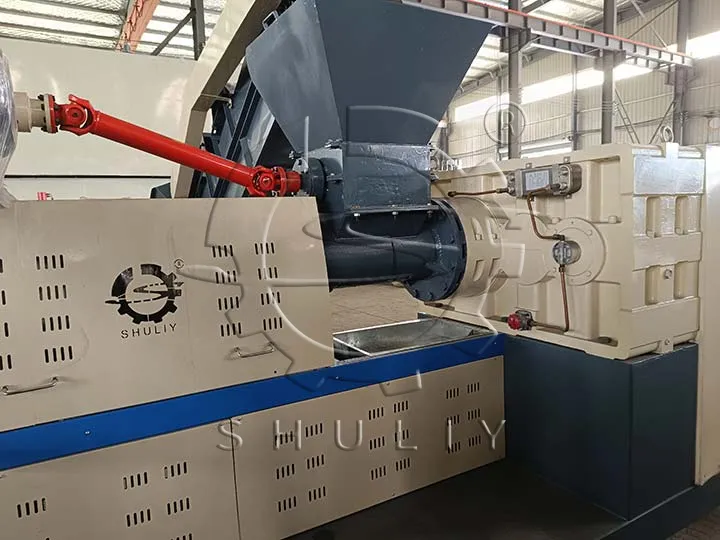

The Plastic Film Granulator consists of essential components such as a feeding port, auto feeder, reducer, heating device (including electromagnetic heating, ceramic heating, and iron heating), screw, motor, mold head, die head, and an electric control cabinet. The machine works by feeding the plastic film waste through the feeding port and auto feeder. The plastic is then melted and extruded through the die head using the rotating screw, which is driven by the motor. The extruded plastic is cooled and cut into small pellets to produce high-quality recycled plastic pellets.

Video of plastic film pelletizing machine

The video shows the complete plastic pelletizing project from the Shuliy group. The output is 1000kg/h. Welcome to watch.

Plastic film granulator heating device

The most effective heating method: electromagnetic heating

The ceramic heating method is always selected by customers from Ethiopia, Congo, Nigeria, Saudi Arabia and so on. The heating effect is also great for a plastic film pelletizing machine.

Recommend equipment for plastic film granulator

Auto feeder

With a special structure and control system, the forced feeder is able to feed the light plastic film into the feed opening of the plastic film pelletizing machine in an even and continuous manner. This helps to avoid the problem of poor material flow or material accumulation during the processing of the pellet machine and ensures that the raw materials can be evenly distributed inside the pellet machine to improve production efficiency.

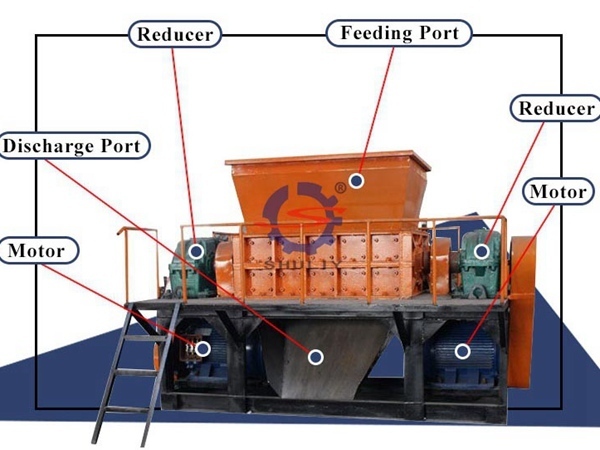

Plastic film crusher machine

A plastic film crusher machine, also known as a plastic film shredder or plastic film grinder, is a specialized equipment designed to crush and reduce plastic films into smaller particles or flakes. It is commonly used in the complete plastic pelletizing line to process waste plastic films and improve their recyclability.

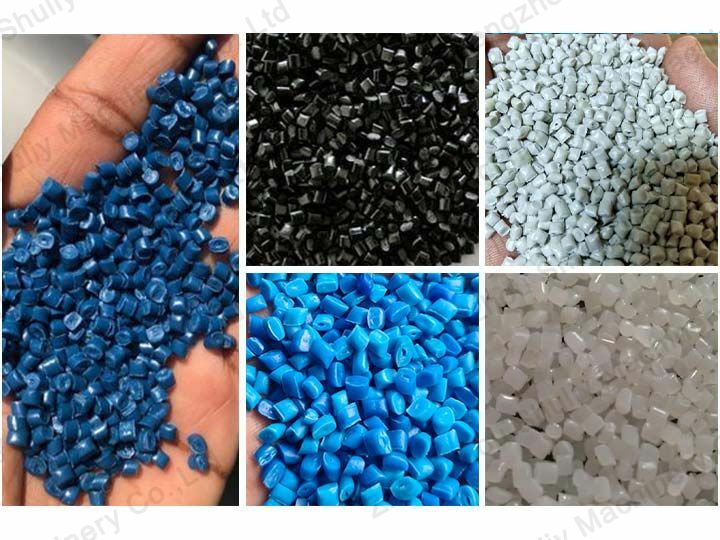

Raw materials of PP PE film granulator

Polyethylene film, Polypropylene film, are the most common materials of Shuliy’s customers. The waste plastic films includes waste packing bags, woven bags, shipping bags and so on.

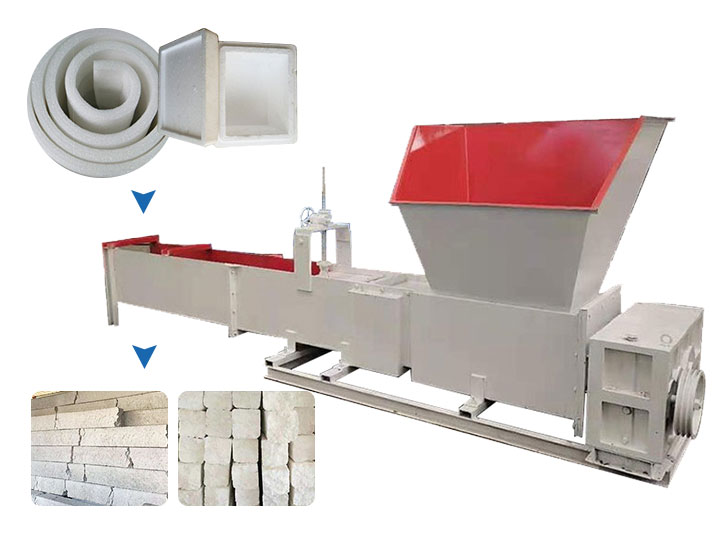

Application of recycled plastic granules

The recycled plastic pellets produced by the PP PE film granulator have a wide range of applications. They can be used to manufacture plastic containers, bottles, barrels, pipes, plastic bags, and films. In the automotive industry, these pellets are utilized for interior parts, body parts, instrument panels, and door panels. Additionally, the pellets are suitable for producing packaging materials, such as plastic films, foam boxes, and protective pads.

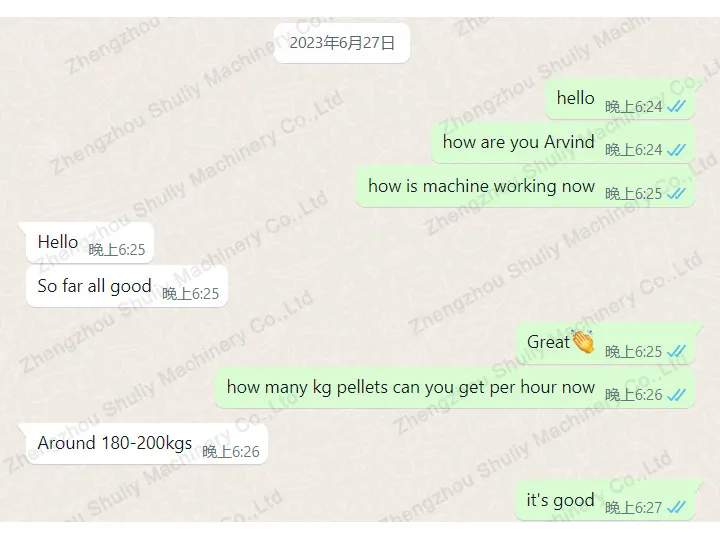

Successful cases of plastic film pelletizing machine

Plastic film granulator shipped to Kenya

One of our customers from Kenya recently purchased the Plastic Film Granulator and achieved a production output of 180-200 kg per hour. With the machine’s efficient performance, they have successfully established their recycling business and are experiencing positive economic benefits.

PP PE film extrusion machine exported to Tanzania

Shuliy MAchinery’s customer from Tanzania recently purchased our PP PE plastic granulator machine. Nowadays, the granulator machine is installed and running well, producing over 400kg of high-quality plastic pellets each day!

FAQs of plastic film extrusion granulator

Question: Can the Plastic Film Granulator handle different types of plastic films?

Answer: Yes, the machine can efficiently process polyethylene film, polypropylene film, waste plastic packing bags, and agricultural films.

Question: What is the output capacity of the Plastic Film Granulator?

Answer: The plastic film pelletizing machine is available in various models, with capacities ranging from 3 tons/day to 7 tons/day.

Question: Are the recycled plastic pellets of high quality?

Answer: Yes, the Plastic Film Granulator ensures the production of high-quality recycled plastic pellets that meet industry standards.

Question: How is the plastic film pelletizing machine’s operation controlled?

Answer: The Plastic Film Granulator is equipped with an electric control cabinet that allows easy control and monitoring of the machine’s operation.

Question: Is technical support provided after the purchase?

Answer: Shuliy Machinery offers comprehensive technical support and assistance to customers after the purchase, ensuring smooth machine operation.

Hot Product

Fibre Shearing Machine | Fiber Shredder for cutting waste cloth

The fibre shearing machine can cut worn-out clothes…

Plastic pellet storage bin | Recycled plastic granules silo

The plastic pellet storage bin is an alternative…

Belt conveyor | Plastic bottle sorting table

Structure of belt conveyor The belt sorting table…

Plastic shredder machine for metal tire shredding

The plastic shredder machine mainly uses the principle…

Pioneering waste plastic water ring pelletizer

Due to the advantages of the water ring…

Vertical foam cutting machine

The Vertical foam cutting machine is dedicated to…

Vertical EPS foam compactor | styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

EPS Granulator | Expanded Polystyrene Foam Recycling Machine

EPS granulator is mainly suitable for foam fast…

Plastic crusher machine for recycling plants worldwide

The plastic crusher machine sold by Shuliy Machinery…