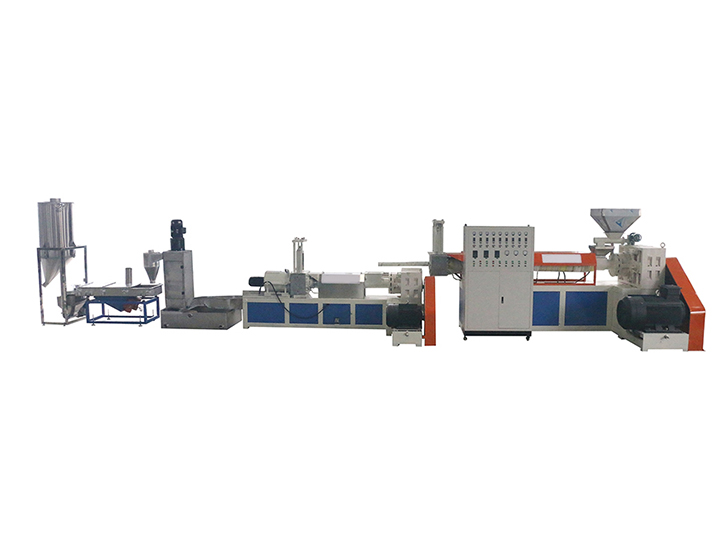

Plastic film recycling granulator

Plastic granulator scope:

Waste plastic granulators are mainly used to process waste polyethylene (PE), polypropylene (PP) and PET. Such as: agricultural film, woven bags, plastic bags, bottles, pots, barrels; plates, wire and cable skins, plastic daily necessities and electrical enclosures. And the recycling and cleaning of HDPE, PP, PE and other floating hard plastics such as used milk bottles, cosmetic bottles, shampoo bottles, blue barrels, used frames, plastic chairs, plastic buckets, etc. in daily life, and then can be used after granulation. From the perspective of energy saving and environmental protection, the user has adopted different schemes and is suitable for the recycling of different waste plastics.

Plastic granulator features:

The plastic granulator unit can process the washed and broken waste polyethylene and polypropylene plastic into particles, and has the characteristics of beautiful appearance, stable quality, wet and dry, environmental protection, energy saving and high output as raw materials for re-forming.

The plastic granulator screw barrel adopts carbon structure steel bar to adjust and temper, shape, nitriding, large torque, gearbox for three-axis two-stage helical gear reduction, gear materials are made of special steel, forged, tempered, rolled After the teeth, it is then carburized and quenched, so the strength is high and the operation is stable.

The plastic granulator has good material for the skeleton of the whole machine, which reduces the resonance caused by the operation of the equipment, and the equipment has a long service life. After the waste is sorted, crushed and washed, it does not need to be dried or dried and dried to produce good particles.

From the raw material crushing, cleaning, feeding to pelleting, the production efficiency is high. The use of high-pressure friction uninterrupted heating system, automatic heating production, continuous heating, energy saving. Plastic pelletizers produce plastic pellets with high density and good plasticization.