100-500 kg/h plastic film washing line is a new trend for recycling business

Our plastic film washing line can meet the needs of most plastic recycling plant and plastic granules manufacturers, and our goal is to help our customers maximize their plastic recycling rates and ensure product quality.

After our plastic film washing line, plastic recyclers can obtain clean and dry film sheets. Next, you can also process these plastic films into plastic pellets and earn high profits by selling them.

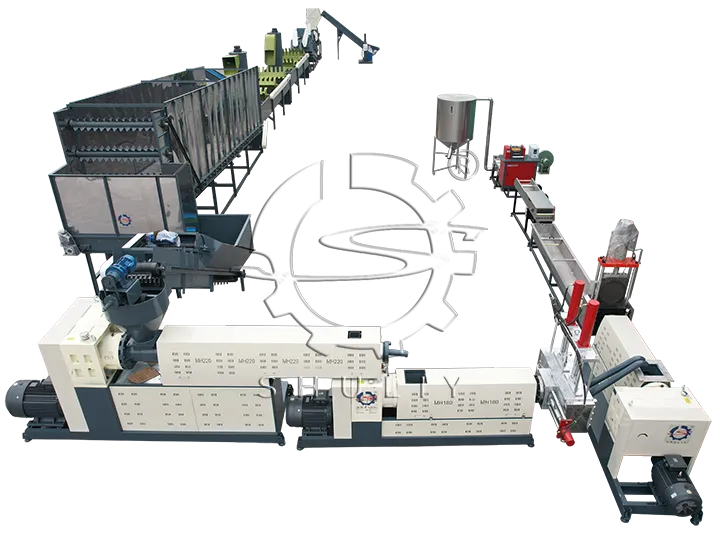

Plastic film washing line introduction

Plastic film washing recycling line is an equipment system specially designed for processing plastic film waste. Its main function is to recycle, wash and process waste plastic film to make it into reusable plastic pellets or raw materials for other plastic products.

The output of our plastic film washing line is usually between 100-500kg/h, this range can meet the needs of most plastic recycling plants. Shuliy Group can also design a higher output recycling line according to your special needs, you can leave your requirements on our website and our business manager will provide you with the most professional solutions.

Working principle of plastic film washing recycling line

Shuliy plastic film recycling and washing plant is equipped with advanced equipment and technologies, including automated control systems, high-efficiency plastic film washing machines, centrifugal dewatering machines, drying equipment and plastic granulator machine.

The application of this equipment and technologies improves recycling efficiency, reduces energy consumption and labor costs, and ensures that the recycled plastic film meets high quality and cleanliness standards.

Plastic film crusher machine

The new angle of the uniquely designed crushing chamber blade allows the plastic crushing machine to cut plastic with the highest performance and lowest current and noise.

Plastic cleaning system

The plastic film washing tank is used to remove dirt from plastic. When PP PE plastic film is rinsed repeatedly, sand, dirt, and stones will be separated out, and dirt on the plastic will be removed at the same time.

Vertical dewatering machine

The vertical centrifugal dryer uses centrifugal force to remove most of the water from the PP PE film directly from the washing tank.

Plastic film pelletizing machine

The plastic pelletizing process is the last step of the plastic film recycling washing line. Clean films need to be made into small plastic pellets by a plastic film pelletizer machine, then they will obtain a high economic value.

What can Shuliy Group do for your plastic film washing line?

Shuliy Group is a company that specializes in the technological development of mechanical solutions for plastic recycling. The core team has been in the plastic recycling industry for over 20 years, aiming to provide the most professional plastic recycling equipment for recycling plants that solve the problem of recycling waste plastics.

Pre-sales service: After receiving our customers’ requirements, our sales manager will contact you in 24 hours. We are happy to introduce to you the price and details of a plastic film washing line and customized plastic recycling solutions.

On-sales service: Shuliy’s plant will load and deliver your ordered equipment as soon as possible. If you have a special requirement like machines with a large output, our professional engineering team will customize and manufacture your special machines immediately.

After-sales service: In terms of installation and commissioning, Shuliy Group will fully support our customers to reach the point where their operators can operate the machines skillfully. We offer two types of installation, one is online instruction and the other is to arrange for our engineers to come to the customer’s factory and train the workers to operate the plastic recycling machines proficiently.