Plastic Pelletizing Machine

Plastic granulator for PP raffia woven bags | Plastic pellet making machine

Plastic Pelletizing Machine

Plastic granulator for PP raffia woven bags | Plastic pellet making machine

Features at a Glance

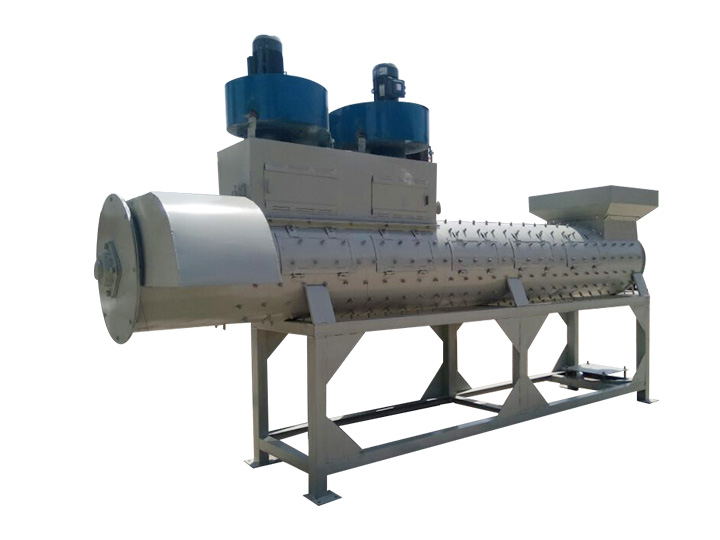

The plastic pelletizing machine can also be called a plastic granulator, serving as a very important recycling machine in plastic waste recycling line. The plastics granulator can be used to melt and pelletize waste plastics such as PP, HDPE, LDPE, LLDPE and ABS for reuse. The final pellets can be put directly back into the plastic production line.

Welcome to send us a message to tell us what your recycling materials are. We will design a proper pelletizing solution for you.

Recycle materials for plastic recycle machine

Shuliy plastic recycle machine can process both post-industrial waste (in-house waste) for plastic producers, and post-consumer waste for plastic recycling factories.

Post-industrial waste: defective products and cut-offs are the common recycle materials, such as LDPE zipper bag production waste, LDPP film scrap, HDPE soft irrigation pipes, bubble wrap, PE/PP packaging bag cut-offs, injection molded products, blow-molded products, thermoformed products, etc.

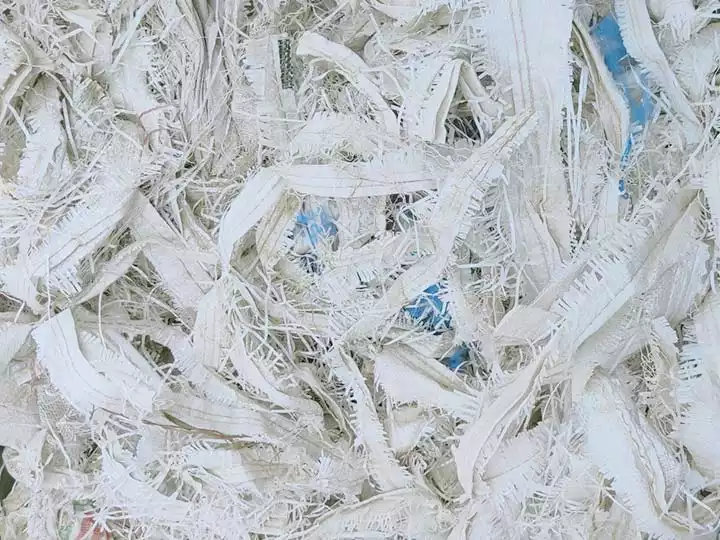

As for the post-consumer waste, the recycle materials are various. They include PP/LDPE/HDPE regrinds, PP raffia bags, used agriculture films, cement bags, plastic lumps/bulks, PP ropes, jumbo bags, woven bags, non-woven sacks, food containers, jerry cans, PP bumpers, electronic and automotive waste, pipes etc.

If your recycle materials are other materials, feel free to consult us.

Technical details of plastic pelletizing machine

The model of this plastic scrap granulator is mainly divided according to the diameter of the screw press.

- The screw material of the recycle machine is 45 # steel, 40CR, 38CRSI. Customers can also customize chrome plating, nitriding, and other processes to extend the service life of the machine according to their plastic recycling characteristics.

- The reducer of the plastic pelletizing machine adopts a hard gear surface reducer. The reducer is an important component of plastic granulator, so quality is particularly important. At present, the quality ranking of common reducers on the market is old-style snail reducer <common reducer <semi-hard gear surface reducer <hard gear surface reducer.

- There are two kinds of die heads for plastic pelletizer machine for sale: electric die heads and hydraulic die heads. The hydraulic die head can change the filter screen without stopping. It is more suitable for material with more impurities, but the cost is higher correspondingly.

- The heating mode of the plastic pelletizing machine is divided into the cast aluminum heating ring, quartz tube heating ring, ceramic heating ring, and electromagnetic heating ring. The heating effect of electromagnetic heating is the best, the temperature can be added quickly and the effect of constant temperature is good, but it is not suitable for processing foam material. The heating method can be comprehensively considered according to the raw materials of the customer and the color of the final product.

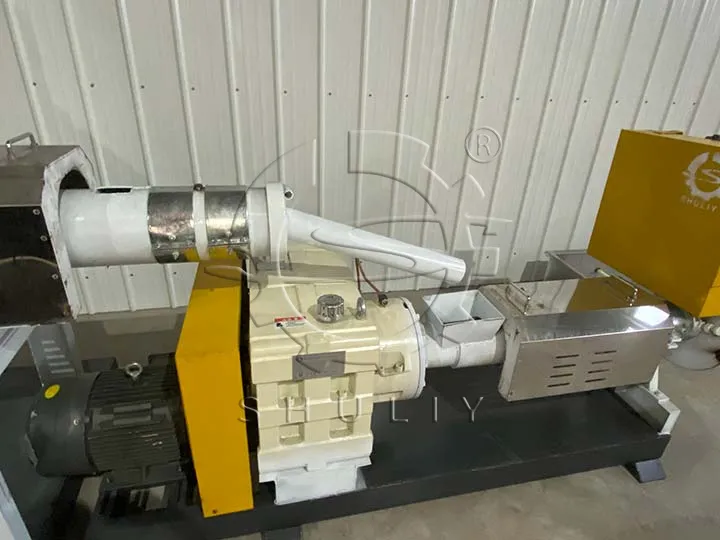

Structure of the plastics granulator

The plastic granulator machine is mainly composed of a feeding port, screw press, press chamber, heating device, discharge port, mold head, reducer, machine body, base, motor, and other parts.

This plastic pelletizing machine is the main machine of the plastic recycling line and can handle a variety of plastic materials. But the plastic granulator machines that handle different materials are not exactly the same. Their appearance is similar, but the diameter of the internal screw, the distance between the screw and the barrel wall, and the length of the screw are all different. They all need to be adjusted according to the material. Therefore, one plastics graulator machine cannot handle multiple materials.

How to operate plastic scrap granulator?

A plastic pelletizer machine for sale is used to melt and extrude plastics of various materials. The following words we will introduce you how to operate it.

1. First, turn on the plastic granulator.

2. Secondly, observe the operation of the plastic recycle machine, and put it into use after there is no abnormal sound or vibration.

3. Thirdly, it is necessary to preheat the plastic film pelletizing machine so that it can melt the plastic. If the temperature is too high, the melted plastic will turn black; if the temperature is too low, the plastic will not melt.

4. Put the crushed material into the feeding port of the plastic granulator, and add a forced feeder for plastic film material to prevent the plastic pelletizing machine from not feeding.

5. The material melts in the squeezing chamber and is pushed out continuously along with the squeezing screw. The material from the main engine will enter the auxiliary engine again for secondary melting and extrusion.

6. The material from the outlet can be put into the cooling tank for cooling.

Video: How does the plastic pelletizing machine work?

The following video shows the complete plastic granulation process, the raw materials are waste plastic films. If you have the same requirements, welcome to contact us about the recycle machine anytime.

Re-usable and high-quality plastic pellets

Pellets produced by recycling machines can be put directly back into the production line, usually for blown film, injection molded items, or pipe extrusion processes.

- On average, post-industrial waste accounts for 4% or more of a production line, so many factories are now equipped with plastics recycling machines to recycle plastic trimmings, in this way, producers can reduce raw material purchasing costs. Since the quality of the trimmings is the same as new, they can be pelletized and used to produce high-quality plastic products.

- Recycling plants collect waste plastic materials from various places. After being washed, these plastic scraps can be recycled into plastic pellets using Shuliy granulators. The plastic recyclers usually add masterbatch or additives in the pelletizing process, so they can change the color and improve granules’ quality.

Heating methods of plastic pelletizing machine

We provide different heating methods, including electromagnetic heating, ceramic heating device and Iron heating. The electromagnetic method is the most efficient one, when you choose a set of mother-baby plastic pelletizer machines, we recommend you choose the electromagnetic method for the host machine. For the second machine, it is available to choose any of the heating methods.

Electromagnetic heating of the plastic granulator machine

Ceramic heating device

Iron heating device

Parameters of plastic pelletizer machine for sale

| Type | 105 | 125 | 135 | 150 | 180 | 200 | 220 |

| Screw diameter | 105mm | 125mm | 135mm | 150mm | 180mm | 200mm | 220mm |

| Spindle speed | 50-70/min | 50-70/min | 40-50/min | 40-50/min | 40-50/min | 40-50/min | 40-50/min |

| Main motor power | 18.5kw | 30kw | 37kw | 37kw | 55kw | 75kw | 90kw |

| Reducer(hard gear) | 200 | 225 | 250 | 250 | 280 | 315 | 330 |

| Weight | 1.3T | 1.8T | 2T | 2T | 2.2T | 2.8T | 3.2T |

| Size | 2.4*0.7*0.7 | 2.6*0.7*0.7 | 2.8*0.7*0.7 | 3.0*0.7*0.8 | 3.2*0.7*0.8 | 3.5*1*1 | 3.8*1.2*1 |

| Output | 150KG/H | 180KG/H | 200KG/H | 300KG/H | 350KG/H | 380KG/H | 420KG/H |

There are a series of plastic granulator machines available. The plastic pelletizing machine type is named based on the screw length. There are also a different heating method for options. For special needs in terms of output, machine materials, etc, we can provide customization services.

Head dies of plastic pelletizing machine

The die head of the plastic pelletizing machine has three types, including an electric gear die head, hydraulic die head, and automatic slag filter. The function of the machine head is to transform the rotating plastic melt into a parallel linear motion so that the plastic melt is introduced into the mold sleeve evenly and smoothly, and the plastic is given the necessary pressure for molding.

Shuliy plastic granulator machines Advantages

1. Reducer, die head, motor, etc. all use the highest equipment currently on the market.

2. The plastic film pelletizing machine can be customized according to customer requirements or raw materials that need processing. Such as the diameter of the screw press, the heating method, the die, the material of the screw press, the material of the machine, etc.

3. Rich production experience. There are many different plastic materials on the market. To process different types of plastics, changes need to be made inside the machine to achieve the best production results. There are many manufacturers who do not understand the material, and mistakenly believe that all the internal structure of the plastic pelletizing machine is the same. So that the machine-made seriously affects the output and quality of the final product.

Choosing a plastic granulator needs to collect much information and need patience, we hope you can get an ideal one.

Successful cases of Shuliy plastics granulator

Shuliy Machinery has exported plastics granulator and other plastic recycle machines to process plastics to many countries.

Plastic granulator feedback video from Ghana customer

We exported a plastic pelletizing machine to Ghana this year and now they have received the machine and started production. They recently sent us a video of the plastic pellet machine at work, with the raw material being used plastic film. They want to make pellets from waste plastic films.

They also told us that they are satisfied with the output of the plastics granulator and it runs smoothly and efficiently. If you are interested in plastic recycle machine, please feel free to consult us and we will contact you as soon as possible.

Related recycle machines to process plastic

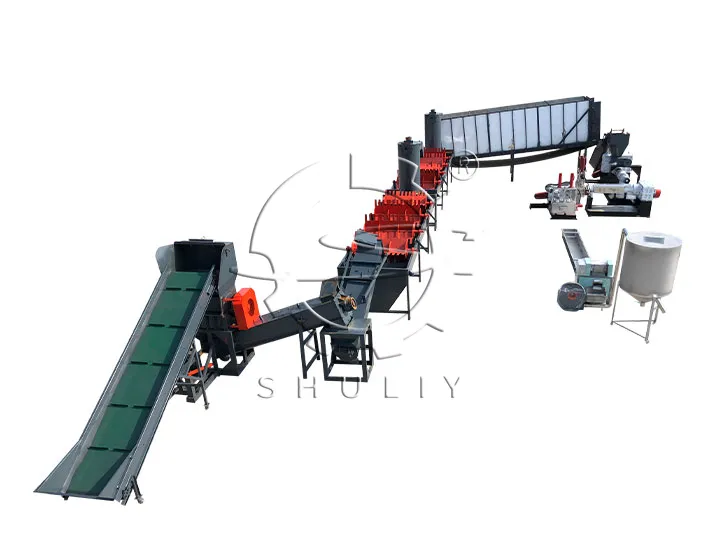

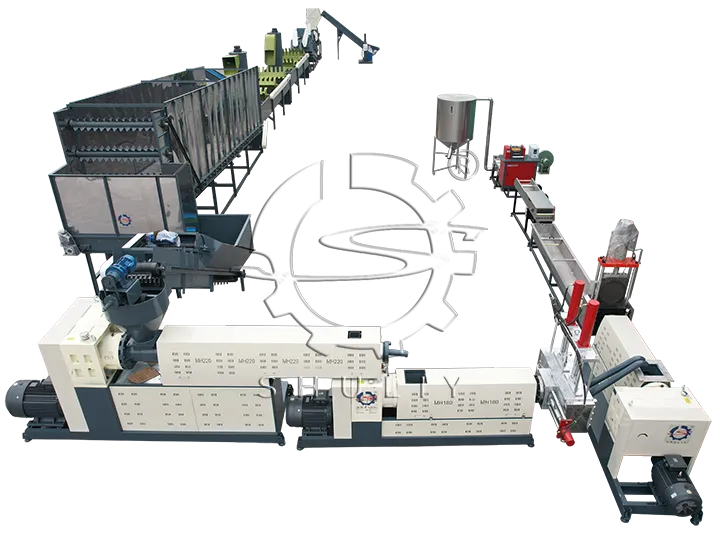

Complete plastic pelletizing line

The whole plastic pelletizing recycling line includes all recycling machines, they are plastic crusher, plastic washing tank, plastic granulator, cooling tank, pellet cutting machine, and pellets silo. We can design and customize a plastic pelletizing line for you, all you need to do is send your machine requirement, plant area, and raw materials.

Plastic crushing machine

A plastic crusher machine is necessary for a plastic recycling plant. The following plastic crusher can shred PP PE into small flakes. If interested, you can contact our sales manager to get more information.

What should we pay attention to in plastic granulation process?

Plastic granulator machines are mainly used to recycle waste plastic film, PP, and PE flakes. It is widely used in the waste plastic recycling industry and is deeply supported and favored by customers. However, in order to better ensure the overall performance of the plastic granulator and prolong the service life of the product, plastic granulator operation should be emphasized. What should we pay attention to when using a plastic film pelletizing machine? There is something we need to point out before operating the equipment.

How to match the plastic pelletizing machine?

The option of a plastic pelletizing machine is flexible, it depends on your quantity of raw materials and your budget. If your waste plastic does not exceed 100 kg, one main engine is enough for your granulation, you should put the head die on the main plastics granulator. If you need to cope with over 100kg of plastic, adding two or three auxiliary engines is an applicable choice.

Plastic granulation process of plastic appliance shell

With the rapid development of modern industrialization, home appliances are also emerging endlessly. Due to the extremely high rate of replacement of home appliances, common home appliances include TV sets, refrigerators, computers, washing machines, etc. The high replacement rate of home appliances has led to a good prospect for the recycling of waste home appliance casings.

Hot Product

Automatic rubber powder production line

The automatic rubber powder production line is used…

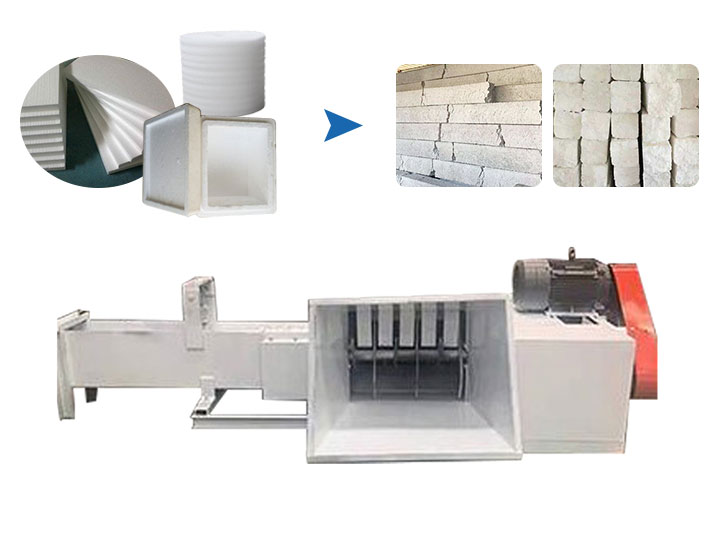

EPS Granulator | Expanded Polystyrene Foam Recycling Machine

EPS granulator is mainly suitable for foam fast…

Horizontal EPS foam compactor

The function of the horizontal EPS foam compactor…

Cotton Waste Recycling Machine | Garment Rags Tearing Machine

The cotton waste recycling machine is mainly used…

Plastic Bag Shredder Grinder Machine

A plastic bag shredder is a kind of…

Electrostatic spray machine | Manual powder coating gun

The electrostatic spray machine is industrial equipment for…

Frictional washing machine for PET bottle recycling

Working process of the frictional washing machine As…

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

Plastic pellet cutting machine | Plastic granule cutter

This plastic pellet cutting machine is the last…