Plastic pipe making machine | PPR HDPE PVC pipe production line

Plastic pipe making machine | PPR HDPE PVC pipe production line

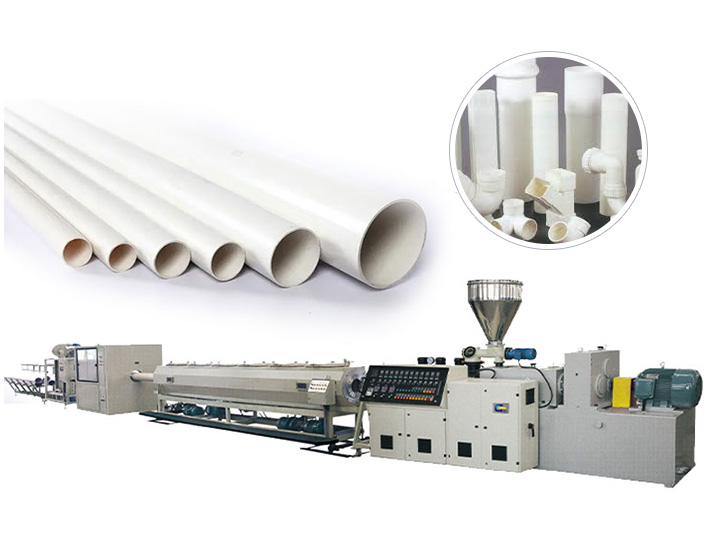

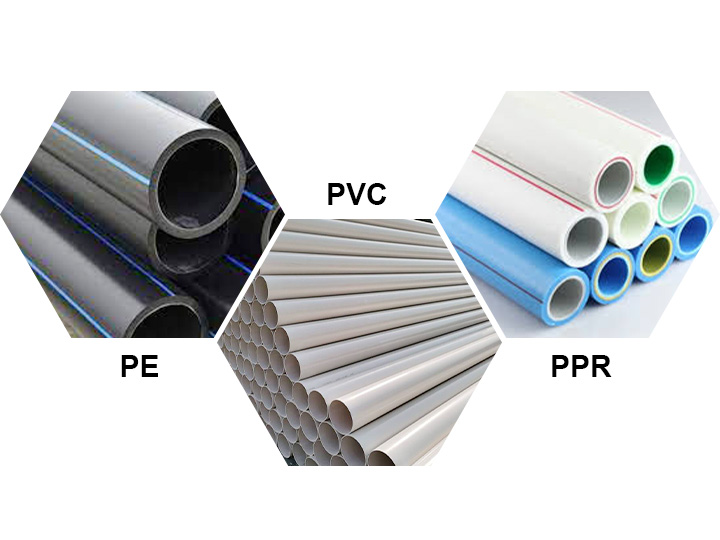

Our company has a full range of plastic pipe extrusion lines, including PVC extrusion lines, PE pipe extrusion lines and PPR pipe extrusion lines, with a wide range of calibers to meet the needs of different customers. Our company will also provide the basic formula for plastic pipe making machine, which customers can easily adjust according to the formula.

Introduction of plastic pipe making machine

GF series plastic pipe production line is mainly used to produce agricultural water supply and drainage, building water supply and drainage cable laying, etc. It can produce PVC pipes with various pipe diameters and wall thicknesses. The production line consists of screw extruder, vacuum setting table, tractor, cutting machine, turning frame and so on. Our company can be equipped with special devices to produce pipes of other materials such as PP, PE, ABS, PPR, etc. according to customer requirements.

PVC pipes application

The main raw material of PVC pipes is PVC resin powder. According to the use of the pipe, it can be divided into the following types: drain pipe, water supply pipe, wire pipe, cable sheath, etc. Specifically, it can be applied to tap water engineering, electrical engineering, construction engineering, sewer engineering, telecommunication engineering, well sinking engineering, salt water engineering, natural gas engineering, etc.

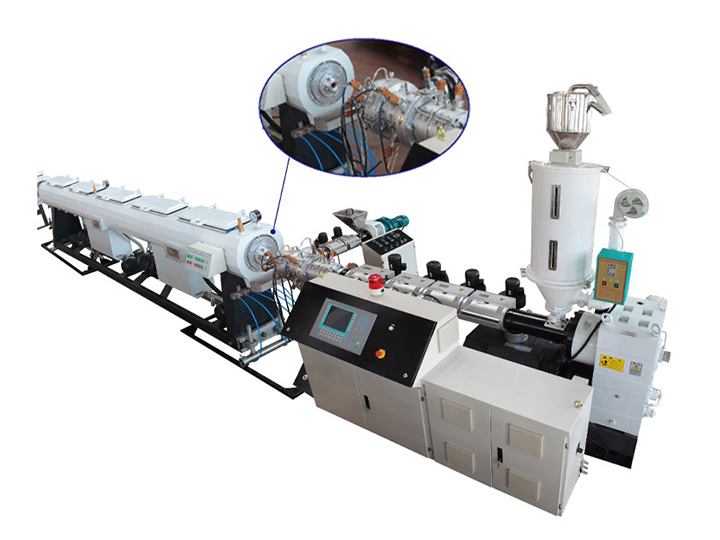

Main process of plastic pipe production line

Mixing production process raw materials → conveying and feeding → conical twin-screw extruder → extrusion die → sizing sleeve → spray vacuum setting box → immersion cooling water tank → ink printing machine → tractor → pipe cutting machine → pipe stacking rack

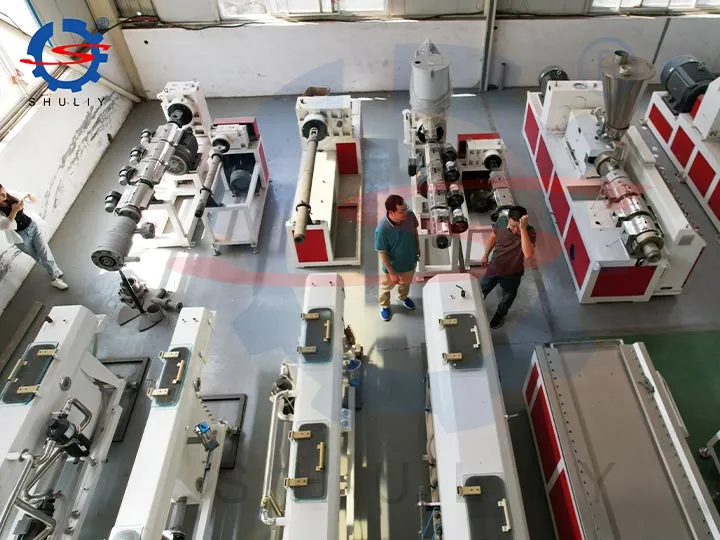

HDPE PVC pipe extrusion machine manufacturers

PVC pipe production line parameters

| Main extruder | 45/90 | 51/105 | 55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 | SJP130/26 |

| Pipe diameter | 16-63 | 16-63 | 16-63 | 16-63 | 63-110 | 200-400 | 500-800 |

| Die head | Single outlet | Single outlet | Double outlet | Double outlet | four outlet | Single output | Single output |

| Downstream equipment | GF63 | GF63 | SGF63 | SGF63 | FGF110 | GF400 | GF800 |

| Total power | 47 | 60 | 70 | 91 | 136 | 212 | 233 |

Among the above parameters, the main extruder SJZ65/132, SJZ80/156 and SJZ92/188 also have larger pipe diameters, which have different die heads and larger power. If you are interested in the bigger size, welcome to consult.

Advantages of plastic pipe making machine

- The plastic pipe production line adopts man-machine interface operation, which has a high degree of automation and saves labor costs.

- Using special screws for pipe, which has a good plasticizing effect.

- The production line adopts the process of vacuum setting and constant temperature control, which eliminates the stress of the pipe.

- The pipe production line can add a wide range of materials, including recycled plastic pellets process made by pelletizers or a pelletizing line.

- The thickness and diameter of the pipes are various, which can meet the different requirements of customers.

How to identify PVC pipe quality

- It is necessary to choose PVC pipes with uniform color and smooth inner and outer walls. The color of PVC drainage pipes that are almost the same is either very white or yellow, and the color is uneven. Some have smooth outer walls and rough inner walls, with needles or small holes. This is not the case. Good quality tubing.

- After we saw the pipe into narrow strips, we tried to fold it by 180. If it is easy to break, it means that the toughness is poor and the quality is average; if it is difficult to be broken, it means that it has toughness, and the toughness is a good quality PVC pipe.

- According to the judgment of the broken stubble of the PVC water supply pipe, if the stubble is fine, it means that the homogenization and strength of the pipe are better, and the pipe is of good quality; if the port is rough, the quality of the pipe is average.

Hot Product

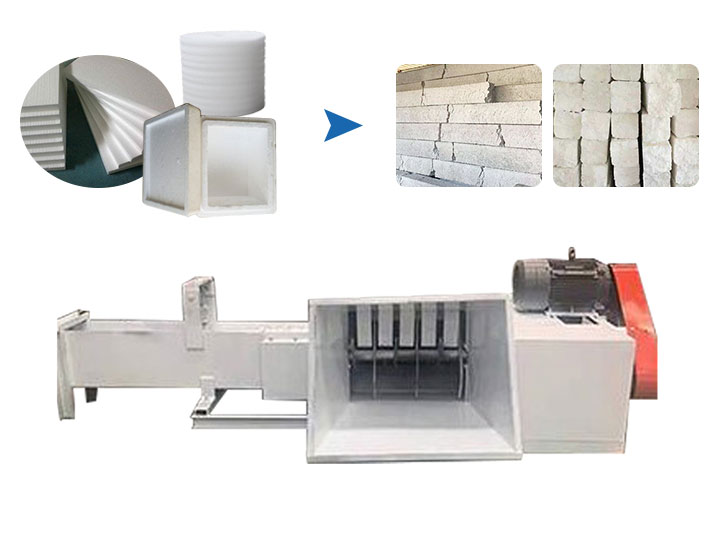

Horizontal EPS foam compactor

The function of the horizontal EPS foam compactor…

Manual powder coating booth

The manual powder coating booth is a small…

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

Plastic Pellet Making machine

A plastic pellet making machine is a recycling…

Plastic pellet bagging machine | Packing machine

Waste plastic needs to be packaged completely after being processed…

Plastic Film Granulator for PP PE LDPE LLDPE Recycle

The plastic film granulator by Shuliy is a…

Plastic Sink Float Separation Washing Tank

Our plastic sink float separation washing tank uses…

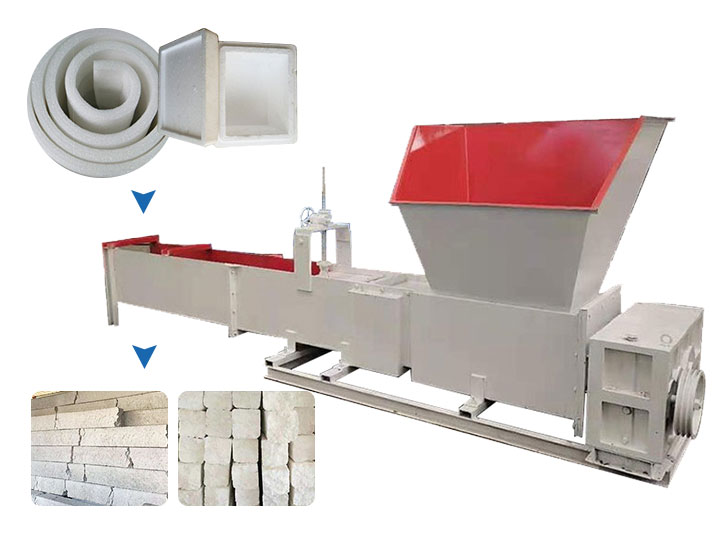

Vertical EPS foam compactor | styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

Plastic Pelletizing Machine

The plastic film pelletizing machine can also be…