Revolutionizing Recycling with Our Advanced Plastic Recycling Equipment in Zambia

At Shuliy Machinery, we take pride in helping businesses and communities around the world turn plastic waste into sustainable opportunities. One of our most recent success stories comes from Zambia, where a forward-thinking client has successfully implemented our plastic recycling equipment to process large volumes of plastic waste into high-value plastic pellets. This case study highlights our plastic recycling equipment in Zambia has empowered this client to achieve both environmental and economic benefits.

The Challenge: Managing Plastic Waste in Zambia

Our client in Zambia faced a growing challenge: managing the vast amounts of plastic waste generated daily in their community. The waste included a mix of plastic oil drums, basins, HDPE bottles, detergent containers, and other household plastic items. These materials, if not properly recycled, would end up in landfills or pollute the environment.

The client sought a reliable and efficient solution to transform this waste into reusable plastic pellets, creating a sustainable business model while contributing to environmental conservation.

The Solution: Advanced Plastic Recycling Equipment for Zambian Client

After thorough research, the Zambian client chose our plastic recycling equipment, specifically tailored to their needs. The equipment package included:

SL-1200 Plastic Crusher: This robust machine is designed to shred large plastic items into smaller, manageable pieces. Its high-performance blades and durable construction ensure efficient processing of tough materials like oil drums and basins.

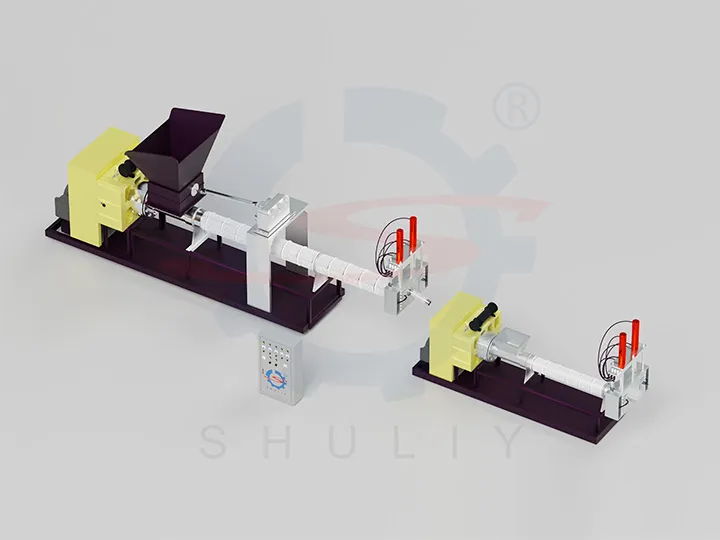

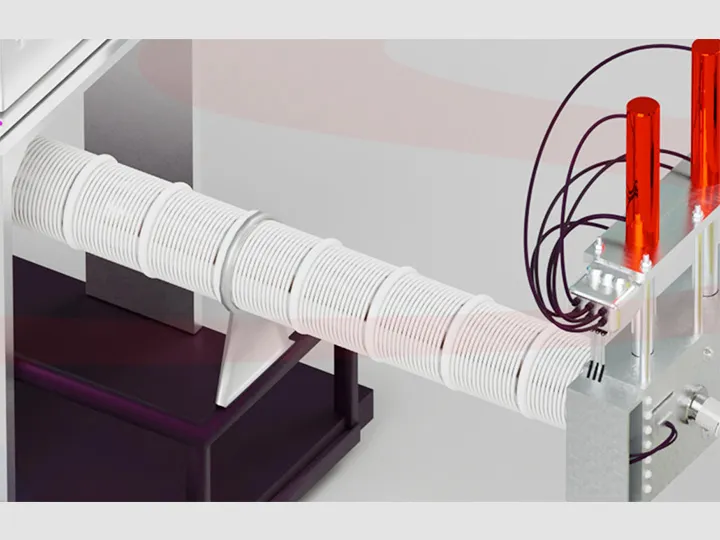

SL-150 Two-Stage Plastic Pelletizing Machine: Equipped with advanced electromagnetic heating technology, this pelletizer machine ensures uniform melting and extrusion of plastic materials. The two-stage design enhances the quality of the final pellets, making them suitable for reuse in manufacturing.

Supporting Equipment: To streamline the recycling process, we provided additional equipment, including:

Automatic Conveyor Belt: Ensures smooth transportation of materials between machines.

Cooling Water Tank: Rapidly cools the extruded plastic strands for efficient pelletizing.

Plastic Pellet Cutter: Cuts the cooled plastic strands into uniform pellets.

To further support our client, we included complimentary spare parts, such as extra blades for the crusher and pellet cutter, replacement screens, and a sharpening stone. These additions ensure the machines remain operational for years to come, minimizing downtime and maintenance costs.

Why Choose Shuliy Machinery?

Our client’s success story is a testament to the reliability and efficiency of our plastic recycling equipment in Zambia. Here’s why businesses worldwide trust us:

- Customized Solutions: We offer tailored equipment packages to meet specific recycling needs.

- Advanced Technology: Our machines, like the SL-150 with electromagnetic heating, deliver superior performance and energy efficiency.

- Comprehensive Support: From installation to after-sales service, we ensure our clients have everything they need to succeed.