Plastic Tube Manufacturing Process

Plastic tubes are an essential component in many industries, from packaging to medical devices. They are flexible, lightweight, and can be customized to meet various requirements. However, the plastic pipe manufacturing process is complex, requiring a high level of precision, expertise and professional equipment.

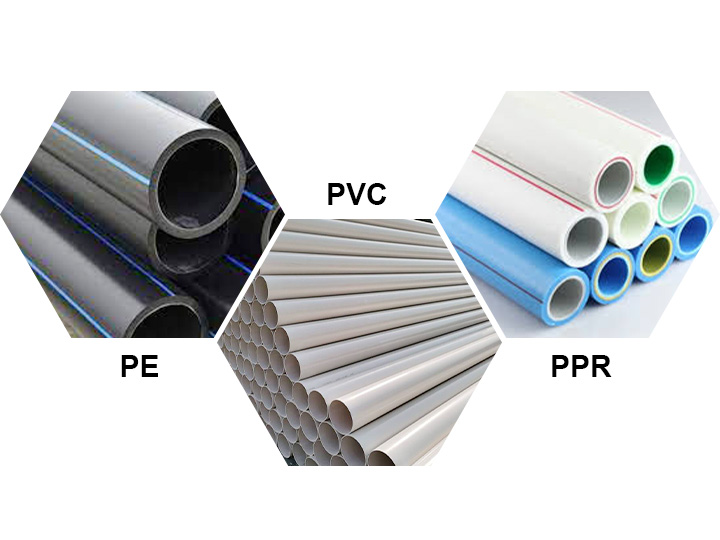

Common materials of plastic pipe

Polyvinyl chloride (PVC): PVC is a popular plastic material used in the manufacturing of pipes due to its durability, chemical resistance, and low cost. It is commonly used in water supply and drainage systems, irrigation systems, and electrical conduits.

High-density polyethylene (HDPE): HDPE is a thermoplastic material that is commonly used in manufacturing pipes due to its high strength, durability, and resistance to chemicals and UV rays. It is used in water supply systems, gas distribution systems, and drainage systems.

Polypropylene (PP): PP is a thermoplastic material that is commonly used in manufacturing pipes due to its high resistance to chemicals and heat. It is used in water supply systems, chemical transport, and sewage systems.

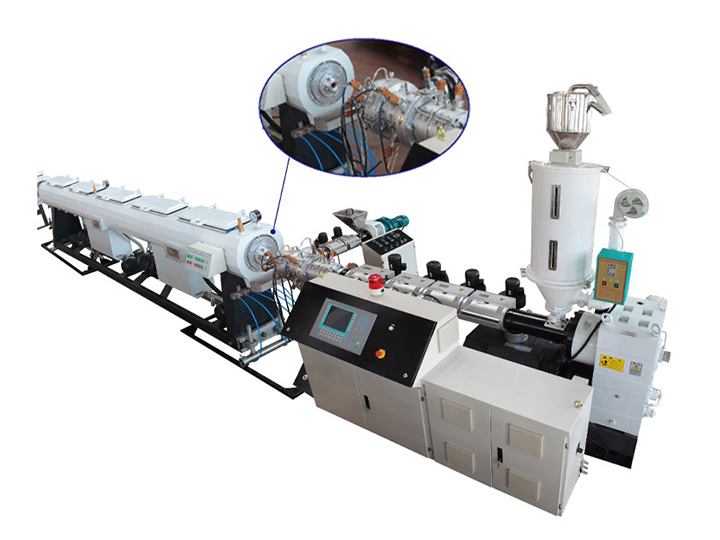

Shuliy plastic pipe manufacturing machine

Shuliy Group provides the complete plastic pipe production line and related machines. Our plastic tubes are made by the extrusion process, which is the most common method for manufacturing plastic tubes. It involves melting raw thermoplastic materials and forcing them through a die to create a continuous tube. This process is highly automated, which ensures consistent tube quality and production efficiency.

Choose Shuliy, Obtain the plastic pipes you want

The plastic tube manufacturing process is complex, but it is also highly efficient and versatile. By using advanced plastic pipe making machines and techniques, manufacturers can create tubes that meet specific requirements for strength, flexibility, and chemical resistance.

If you are looking for a reliable plastic pipe manufacturing machine supplier, make sure to choose a manufacturer with expertise in extrusion, molding, and finishing techniques. We believe choosing Shuliy Group is your best option. If interested, you can leave your requirement on our message form.Our professional project manager will contact you soon.