Rigid Plastic Shredder Machine

Industrial shredding grinding machine for post-consumer / post-industrial hard rigid plastics)

Rigid Plastic Shredder Machine

Industrial shredding grinding machine for post-consumer / post-industrial hard rigid plastics)

Features at a Glance

Shuliy rigid plastic shredder machine is also called a plastic grinder machine, Shuliy provides different models and outputs according to your needs. Shuliy industrial shredder machines have been shipped to Ethiopia, Congo, Saudi Arabia, Nigeria, Germany, the UK, and so on, it is an indispensable recycle machine for a complete plastic pelletizing and recycling line.

Rigid plastic shredder machine introduction

A rigid plastic shredder machine is a highly efficient plastic recycling machine designed to process rigid plastics. It is widely used in the plastic recycling industry, aiming to quickly and efficiently shred hard plastic waste into small flakes.

The common recycle materials are milk bottles, cosmetic tubes, car bumpers, waste automotive parts, electric waste, PVC pipes, plastic barrels, edge trims of injection molded products, HDPE containers, HDPE bottles, oil drums, plastic pallets, e-waste scrap, chemical drums, plastic crates, etc.

This type of industrial electronic shredder machine for recycling has strong cutting capabilities and a durable design, making it capable of handling different types and shapes of hard plastic materials, transforming them into easily manageable flakes. The hard plastic shredder machine effectively reduces the volume of plastic waste, facilitating subsequent processing and recycling, while also helping to minimize the environmental impact of waste and achieve sustainable plastic recycling and reuse.

Video of rigid plastic shredder machine for recycling

Structure of Shuliy Industrial Shredder

The main structure of a hard plastic shredder consists of a feeding port, crushing chamber, blades, knife frame, screen, and discharge port.

Feed inlet: The feed inlet of an industrial plastic grinder machine is used to put the recycle material into the interior. The design and size of the feed opening can be adjusted according to different crusher models and processing capacities.

Crushing chamber: The crushing chamber is the space inside the rigid plastic shredder machine for crushing plastic raw materials. It usually consists of one or more pairs of blades, which cut, tear, and crush the plastic materials under high-speed rotation.

Blade: The blade is one of the most important parts of the rigid plastic shredder machine, the blade is made of 60Si2Mn with high hardness and wear resistance.

The design of the knife frame should take into account the number of blades, arrangement and installation position to ensure that the blades can be evenly and efficiently for the crushing of plastic flakes. Usually, shredders for rigid materials have larger blade clearances. Compared to soft material shredding.

The knife frame of the industrial shredder machine for recycling is usually fixed with multiple pairs of blades, which may be rotating blades or fixed blades, for crushing the plastic raw materials.

The knife frame has good stability and balance to ensure that the operation of the crusher is stable and safe. At the same time, the knife frame is easy to install and remove, and easy to replace and maintain the blade.

The screen of the plastic grinding machine is used to control the size of the plastic flakes being pulverized. It ensures that only compliant particles pass through, while larger particles are retained for further pulverization. For hard plastics, the screen diameter is typically 20mm to 26mm.

Hard plastic shredder machine parameter

| Type | SL-600 | SL-800 | SL-1000 |

| Output | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Blade width | 600cm | 800cm | 1000cm |

| Blades qty | 10pcs | 10pcs | 10pcs |

| Blades material | 60Si2Mn | 60Si2Mn | 60Si2Mn |

| Power | 30kw | 45kw | 55kw |

Shuliy provides small plastic grinding machines for small recycling plants, the lowest capacity is 400 kg/h. If you are a new entrepreneur starting out in the recycling business, feel free to contact us, we will give you a customized recycling solution and the best plastic scrap grinding price.

Features of rigid plastic shredder machine

The industrial grinder machine is highly efficient. hard material plastic crusher machine adopts powerful cutting force and high-speed rotating blade, which can quickly shred hard plastic materials into small particles or fragments, improving production efficiency. The rotor is specially customized with a large rotating diameter to maximize plastic crushing.

The plastic scrap grinding machine is versatile: the grinder for recycling is suitable for processing all kinds of hard plastic materials, such as PVC pipes, HDPE bottles, plastic drums, electronic waste, automotive bumpers, thermoformed food containers, etc., with strong adaptability.

The rigid plastic shredder is sturdy and durable. The blades of the hard material plastic shredder machine are made of 60 silicon diamanganese, and the body is made of high-quality materials and exquisite manufacturing process, which has good durability and stability, and can run stably for a long time.

Low noise: the hard plastic shredder is optimized to reduce the noise level during operation, providing a better working environment.

Additional pictures of industrial shredder machine

Sharpener for plastic grinder blades

For shredders with output of more than 500kg/h, the knives are usually touched once in 2-3 days to ensure the shredding efficiency. A knife sharpening machine is a special equipment for grinding and repairing the blades of shredder, which plays an important role in the process of plastic crushing and recycling.

The fully automatic knife sharpening machine we offer is an advanced knife sharpening equipment, usually equipped with an advanced control system and sensors, which can realize precise blade sharpening and repair to ensure the productivity of the shredder and the service life of the blades.

Applications for rigid plastics

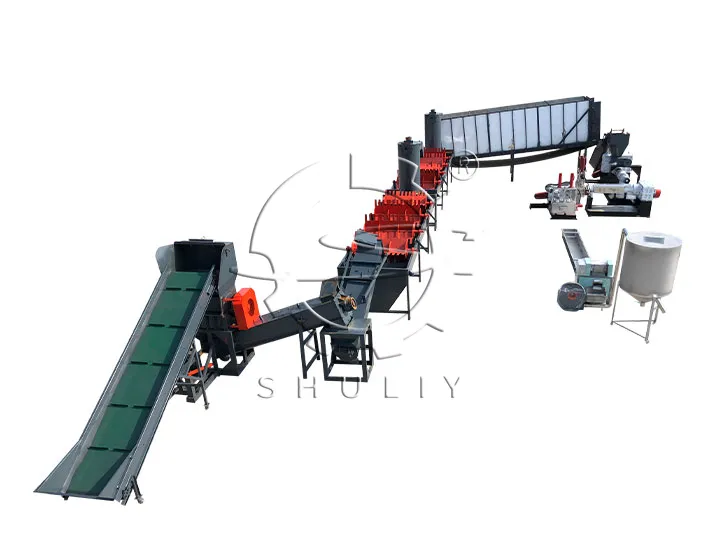

Plastic washing and crushing plant

The plastic washing and crushing line includes one plastic shredder, one or more washing rinsing tanks for rigid plastic, plastic dewatering machines and conveyors.

If your have rich plastic waste, welcome to contact us, our project manager will customize a recycling solution and 3D painting for your reference. We will design the solution and machines according to your materials’ cleanliness and end products’ requirements.

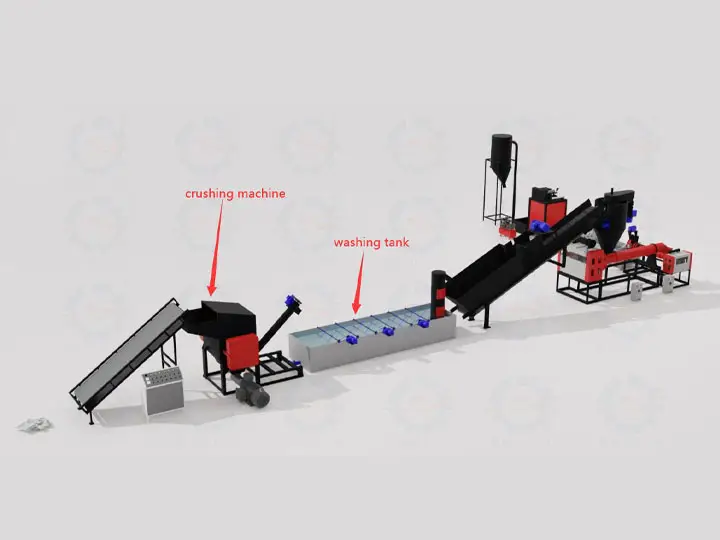

Plastic pelletizing plant

The plastic pelletizing line consists of one plastic crusher, plastic washing tanks,one plastic granulator and a plastic pellet cutter.

The plastic pelletizing plant turns rigid plastics into recycled plastic pellets, which can be used to manufacture plastic products again.

The final plastic pellets can be sold at a good price and can get a high profit for recycling plants.

Inquiries for hard plastic shredder machine

To get the latest plastic scrap grinder price, send us a message by using the form in the right corner.

Our project manager will send you a plastic grinding machine quotation as soon as possible.

Hot Product

Waste tire recycling line | rubber granules making machine

The waste tire recycling line uses advanced tire…

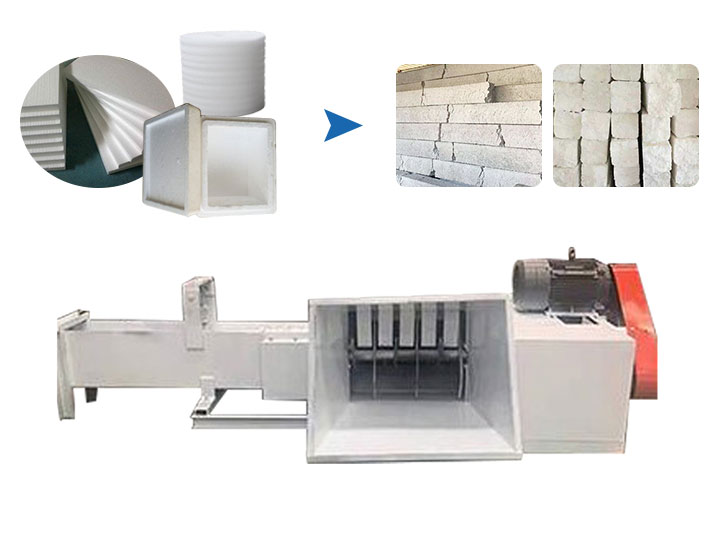

Horizontal EPS foam compactor

The function of the horizontal EPS foam compactor…

Plastic Film Granulator for PP PE LDPE LLDPE Recycle

The plastic film granulator by Shuliy is a…

Horizontal Styrofoam Shredder

A horizontal styrofoam shredder is mainly used to…

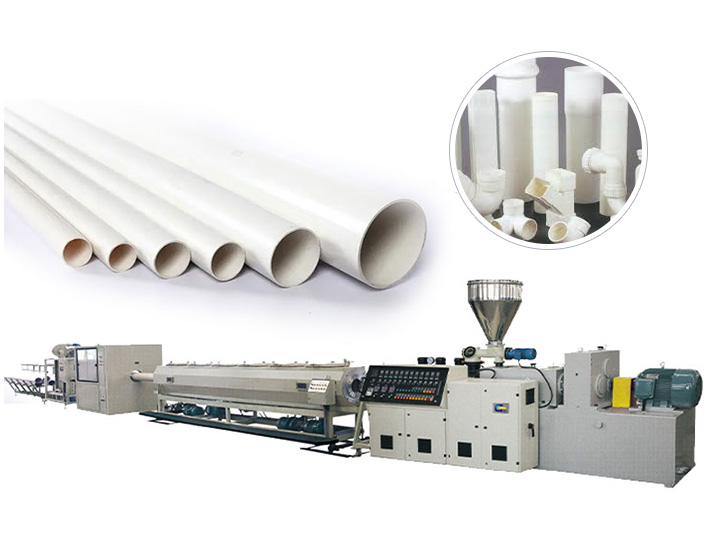

Plastic pipe making machine | PPR HDPE PVC pipe production line

Our company has a full range of plastic…

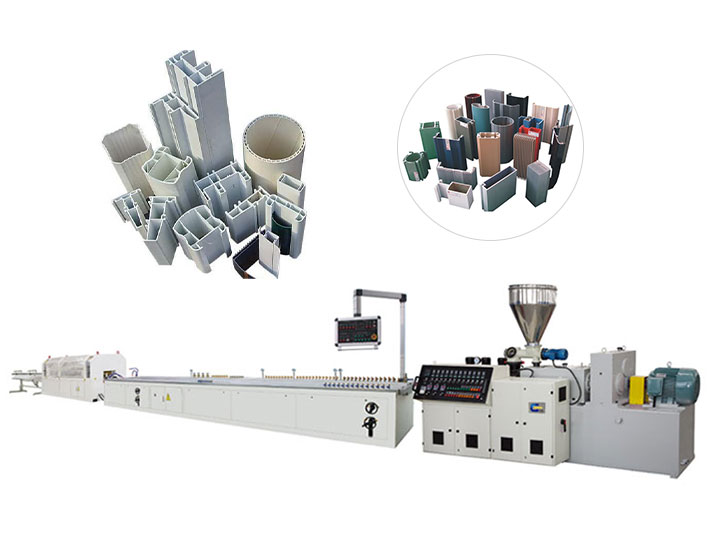

Plastic profile extrusion line | PVC ceiling making machine

Shuliy plastic profile extrustion line is a professional…

Electrostatic spray machine | Manual powder coating gun

The electrostatic spray machine is industrial equipment for…

Fibre Shearing Machine | Fiber Shredder for cutting waste cloth

The fibre shearing machine can cut worn-out clothes…

Plastic Bag Shredder Grinder Machine

A plastic bag shredder is a kind of…