PET chupa flakes maji ya moto tank ya kuosha

Mashine ya kusafisha yenye joto la juu | PET flakes mashine ya kuosha moto

PET chupa flakes maji ya moto tank ya kuosha

Mashine ya kusafisha yenye joto la juu | PET flakes mashine ya kuosha moto

Vipengele kwa Mtazamo

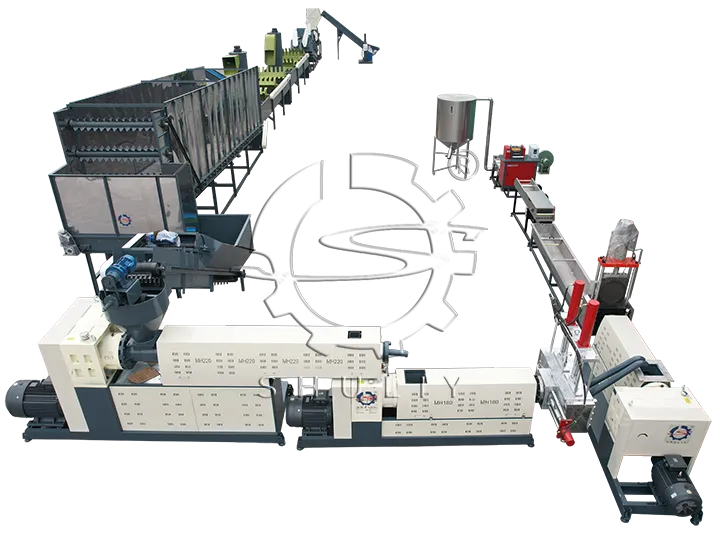

Tangi ya kuosha maji ya moto yanafaa kwa Mstari wa kuchakata chupa za PET. Inatumika kuosha kipande cha plastiki kwenye maji ya moto na sabuni. Mashine ya kusafisha joto la juu ni hatua ya tatu katika mstari wa kuchakata chupa za PET. Itafanya flakes za PET kuwa safi zaidi.

Faida za tank ya kuosha maji ya moto

Mashine ya kusafisha joto la juu ni muundo wa juu wazi na kazi za udhibiti wa joto otomatiki, uhifadhi wa joto, na kuchochea. The faida za tank ya kuosha moto ya PET ni pamoja na uhamishaji wa joto haraka, tofauti kubwa ya halijoto, na kusafisha kwa urahisi. Zaidi ya hayo, tanki ya kuosha maji ya moto ya PET inaweza kuosha flakes vizuri, kuokoa muda, kuendeleza ufanisi wa kuosha.

Utumiaji wa mashine ya kuosha moto ya chupa ya PET

Inatumika sana katika plastiki taka na tasnia zingine kama inapokanzwa, na kusafisha matibabu. Tangi la kuosha maji ya moto linafaa hasa kwa viwanda vidogo, vya kati na vikubwa vya kusafisha nyuzi za kemikali. Na inaweza kupitisha muundo uliofungwa kabisa kulingana na mahitaji ya kiteknolojia.

Soma zaidi: Je! chupa za PET zinaweza kufanya nini baada ya kuchakata tena

Vipengele vya tank ya kuosha maji ya moto

Tangi ya kuosha maji ya moto ni vifaa muhimu kwa Mstari wa kusafisha chupa za PET. Kupitia inapokanzwa kwa maji na matumizi ya viongeza vya kemikali, nyenzo husafishwa vizuri zaidi. Tangi inaweza kubinafsishwa kulingana na mahitaji halisi ya wateja.

Muundo wa nje wa tanki ya kuosha maji ya moto ya PET:

- Mwili wa tank: kumaliza kioo kwenye uso wa ndani

- Jalada la juu: vifuniko viwili vilivyo wazi vinavyohamishika, rahisi kusafisha, na matibabu ya kumaliza kioo kwenye nyuso za ndani na nje (ukwaru Ra ≤ 0.4pt).

- Muundo wa chini wa tanki la ndani: huchakatwa kuwa Pembe ya R kwa kuzungushwa, na hakuna Pembe iliyokufa baada ya kulehemu na kung'arisha na mwili wa tanki la ndani, na nyenzo iliyosafishwa haina uhifadhi.

- Njia ya matibabu ya uso wa shell ya nje: Kioo - kumaliza matte iliyosafishwa.

- Kifaa cha kuchochea: kituo cha juu kinachochewa. Shaft ya pato ya kipunguzaji na shimoni ya pala imeunganishwa na sleeve inayoweza kusongeshwa kwa disassembly rahisi na kusafisha.

- Kasi ya kuchochea: 15 ~ 120r/min (kasi ya mara kwa mara); Fomu za paddle: aina ya sura, aina ya nanga, aina ya blade, aina ya turbine, nk (kulingana na mahitaji ya mchakato).

- Fomu ya kusaidia: aina ya tubular.

- shimo la ufunguzi wa kila ghuba na plagi bomba na mahali pa kulehemu ya ndani tank mwili kupitisha flanging mchakato arc mpito, ambayo ni laini na rahisi kusafisha bila Pembe kufa, na nzuri katika kuonekana.

Vigezo vya tank ya kuosha moto ya PET

| Mfano | SL-500 |

| Urefu | 2 m |

| Kipenyo | 1.3m |

| Unene wa nje | 4 mm |

| Unene wa chini | 8 mm |

| Nyenzo | Carton chuma |

| Nguvu | 4kw |

| Njia ya kupokanzwa | Umeme na mvuke |

- Kiasi: 5L, 10L.

- Njia ya kupokanzwa: tumia makaa ya mawe au gesi asilia kwa kupokanzwa. Maji ni chombo cha kupokanzwa, huzalisha nishati ya joto ili kupasha joto nyenzo kwenye tanki.

- Nyenzo inapokanzwa joto: 90 ℃ au chini

- Udhibiti wa joto: joto hupimwa na kudhibitiwa kwa kuunganisha thermocouple na mtawala wa joto, na joto la nyenzo linaweza kubadilishwa.

Kwa nini uchague mashine ya kuosha moto ya Shuliy PET?

Kwa mnunuzi wa mara ya kwanza

Shuliy Group inaweza kutoa huduma mbalimbali za kina ili kuhakikisha kwamba wateja wanapokea mashine za ubora wa juu za kuosha PET zinazokidhi mahitaji yao, na kwamba wanaweza kuzitumia kwa ufanisi kwa muda mrefu.

Bidhaa za ubora wa juu: Kikundi cha Shuliy kinajishughulisha na utengenezaji na uundaji wa mashine za kuchakata plastiki kwa lengo la kuwapa wateja mashine zenye ubora wa hali ya juu.

Usafirishaji na Usafirishaji: Tunaweza kushughulikia vipengele vyote vya usafirishaji na vifaa, ikiwa ni pamoja na kupanga usafirishaji wa mashine na vifaa hadi vinapopelekwa, kushughulikia kibali cha forodha na hati, na kuratibu na watoa huduma wa vifaa vya ndani ili kuhakikisha uwasilishaji kwa wakati na kwa ufanisi.

Ufungaji na uagizaji: Shuliy inaweza kutoa huduma za usakinishaji na uagizaji kwa mashine na vifaa vya kuchakata PET tunazosafirisha, kuhakikisha kuwa vimewekwa ipasavyo na tayari kutumika.

Kwa mteja wa kurudia

Shuliy ina wateja wengi wa kimataifa ambao walinunua mashine zetu za kuchakata mara kadhaa. Wengi wao tayari wana uhusiano mkubwa wa kihemko kwa chapa ya Shuliy na wamekuwa waaminifu kwetu kwa muda mrefu. Walinunua mmea mzima wa kuosha PET kutoka kwetu na kisha akachagua vifaa vyetu vya kuosha au kusagwa kutoka kwetu tena. Shuliy Group inathamini imani na usaidizi wao.

Bidhaa Moto

Pipa la kuhifadhia pellet za plastiki | Silo ya CHEMBE za plastiki zilizosindikwa

Pipa la kuhifadhia pellet za plastiki ni njia mbadala…

Mashine ya kukata pellet ya plastiki | Mkataji wa granule ya plastiki

Mashine hii ya kukata pellet ya plastiki ndiyo ya mwisho...

Mashine ya Kusafisha Filamu za Plastiki

Mashine ya kuchakata filamu za plastiki ina ufanisi mkubwa…

EPE EPS Foam Granulating Line

Laini ya granulating ya povu ya EPS inafaa kwa...

Mashine ya Plastiki ya Pelletizing

Mashine ya kutengenezea filamu ya plastiki pia inaweza kuwa...

Mashine ya kulisha otomatiki | Feeder ya kulazimishwa kwa kuchakata tena plastiki

Mashine hii ya kulisha kiotomatiki imeundwa kuiga...

Kichujio cha gesi taka | Mfumo wa kuchuja wa kuchakata tena plastiki

Matibabu ya gesi ya bomba la maji ni kiwango cha kisasa…

Usafirishaji wa kupanda mkanda | Mashine ya usafirishaji iliyojumuishwa

Conveyor ya kupanda mkanda ni mashine muhimu…

Mashine ya kusaga plastiki | Kichujio cha chupa ya plastiki

Mashine ya kusaga plastiki inayouzwa na Shuliy Machinery…