Vertical EPS foam compactor | styrofoam recycling densifier

Vertical EPS foam compactor | styrofoam recycling densifier

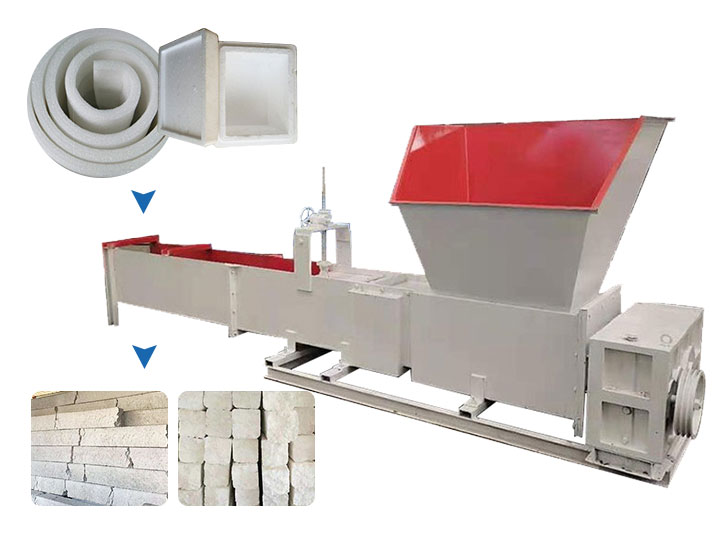

Vertical EPS foam compactor is one of the plastic foam recycling equipment. Because of the large volume of the plastic foam, the transportation is very different, the EPS foam cold compactor can compact the plastic foams easily. A foam compactor machine is a set of energy-saving equipment for waste foam recycling, which improves economic benefits for the related practitioners. Similar to the horizontal foam compactor, the vertical styrofoam compactor has a high compression ratio, with no need to add chemical materials for cold pressing and no peculiar smell.

EPS compactor introduction

As the name implies, the foam cold press machine compresses the materials to reduce the volume of the waste foam and effectively solves the problems of the large volume of EPS, EPE foam, the difficulty of recycling, and the inconvenience of transportation. Different from foam melting machine, it does not produce heat during the time.

Advantages of styrofoam recycling densifier

- The foam densifier can compress the foam by 40 times, which provides great convenience for transportation.

- There is no need to add any other chemical materials during compression so that no peculiar smell can be produced.

- Various outputs available. For example, SL-300, SL-400.

- Easy to feed, use and maintain. It is easy for workers to operate.

Foam compactor machine working principle

Styrofoam compactoris mechanical equipment that extrudes dense foam blocks according to the principle of pressure generated by spiral rotation. The foam densifier machine performs cold pressing and compression processing on the raw material. When in use, the operator only needs to put the foam into the hopper of the EPS foam compactor, and the foam will be crushed and compressed by the crushing mechanism of the polystyrene densifier. After being processed by the screw mechanism, a square foam plastic compression block is produced.

Video of EPS/EPE foam densifier

Parameters of the polystyrene compactor for sale

| Type | Machine size (mm) | Inlet size (mm) | Power (KW) | Capacity (KG/H) |

| 300 | 3000*1400*1400 | 1100*800 | 11 | 150 |

| 400 | 4600*1600*1600 | 1200*1000 | 22 | 250 |

The above are the two models of our vertical EPS compactors. We also offer other models for different demands. The machine size and outputs can be customized based on customers’ needs.

Preparations before using the foam compactor machine

- Before starting the EPS compactor, check whether the mechanical and electrical parts of the equipment are normal.

- Operate the device according to the operation panel instructions

- Debug the styrofoam compactor.

- Set the operating parameters of the equipment

- After the completion of various tasks, the equipment is running, and the foamed plastics are compressed into blocks through the crushing mechanism – compacting mechanism – forming mechanism.

Operation Precautions

- The styrofoam compactor needs to be filled with gear oil before starting to start normally.

- After starting, the material can be directly fed, and the discharge port has a pressure plate that can be adjusted up and down.

- When the material is discharged for the first time, the material that has just started to come out is scattered due to insufficient pressure. The pressure plate is lowered by about 5 cm, and the bulk material is returned to the EPS foam compactor to continue feeding and extrusion. During the period, the pressure plate can be adjusted upwards appropriately, and the material is formed at the same time. The platen is flat front and rear.

- In the production process, people should always pay attention to whether the discharge speed is uniform. If the feeding and discharging are slow all the time, the pressure plate needs to be adjusted upward by about 5MM.

- Every 7 working days, it is necessary to check the oil level of the gear oil and whether the screws are loose, and perform daily maintenance.

Successful case of EPS compactor

The foam compactor sent to Malaysia received great feedback. The customer is from Malaysia, he has his own plastic recycling plant in the local area. His main raw material is mainly plastic foam. Due to the large size of the foam scrap, it takes up a lot of space in his factory, and it is very difficult to transport. Therefore, he wanted to purchase an EPS compactor to compress the foam. He found Shuliy Group online and immediately contacted our account manager. Through communication, he decided that this was the machine they wanted and quickly placed an order.

Once our styrofoam compactor arrived at the customer’s factory, the customer used it immediately and it worked so well that they sent us a feedback video.

Hot Product

PET Plastic Bottle Recycling Machine

Our complete PET bottle recycling line is an…

Rubber powder production line | waste tire recycling plant

The rubber powder processing line is specialized for…

PET bottle flakes hot water washing tank

The hot water washing tank is suitable for…

Strand Pelletizer Machine for Rigid Plastic Recycling

Strand pelletizer machine offer recycled pelletizing technology for…

Waste Plastic Crusher for PP LDPE HDPE Recycling

A waste plastic crusher cuts plastic materials into…

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

Cotton Waste Recycling Machine | Garment Rags Tearing Machine

The cotton waste recycling machine is mainly used…

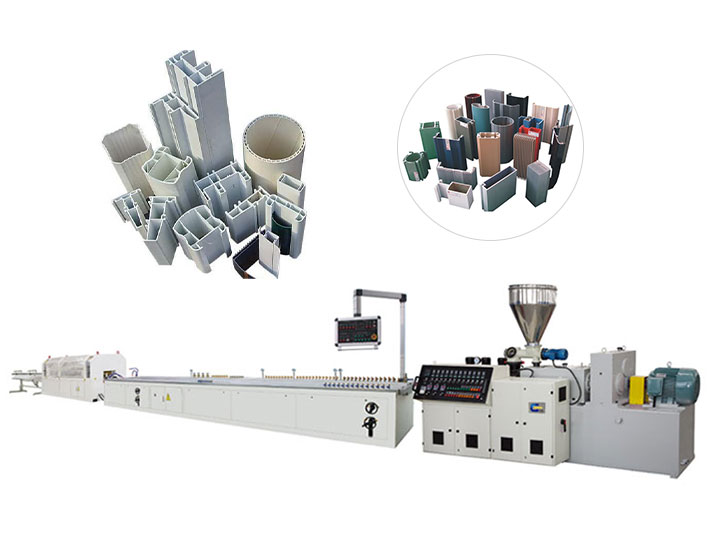

Plastic profile extrusion line | PVC ceiling making machine

Shuliy plastic profile extrustion line is a professional…

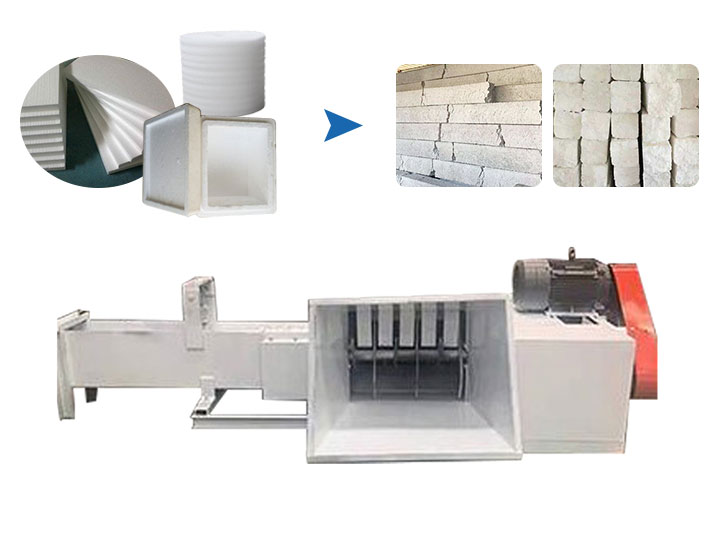

Horizontal EPS foam compactor

The function of the horizontal EPS foam compactor…