Làm thế nào để xử lý tái chế pallet xốp? Máy & Giải pháp

Tái chế pallet xốp có thể được chia thành các bước sau. Chúng tôi đề xuất các phương pháp sau để giảm khối lượng, chi phí vận chuyển và lưu trữ một cách hiệu quả, đồng thời chuyển đổi vật liệu xốp thải thành tài nguyên có thể tái sử dụng.

Video sau đây trình bày cách xử lý việc xử lý xốp bằng thiết bị tái chế tại nhà máy Shuliy.

Nghiền bọt – giảm thể tích ban đầu

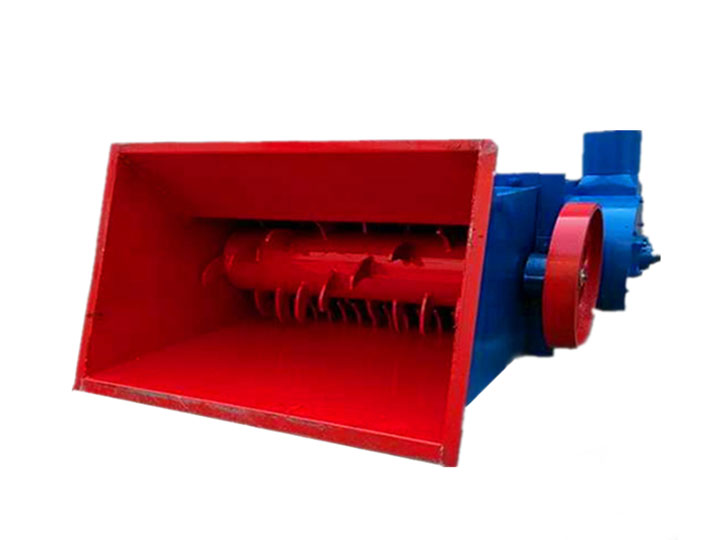

Pallet xốp lần đầu tiên được đưa vào một máy nghiền xốp cho quá trình nghiền ban đầu. Mục đích của bước này là cắt các pallet xốp thành các miếng nhỏ (bột thô), giúp giảm đáng kể kích thước của chúng và tạo điều kiện thuận lợi cho quá trình xử lý tiếp theo.

Đầu vào của máy nghiền bọt ngang Shuliy nằm ngang với sàn, giúp cải thiện đáng kể tốc độ cấp liệu. Bọt nghiền được thổi bằng máy thổi vào máy nóng chảy cho bước xử lý tiếp theo.

Nóng chảy - đậm đặc hơn nữa

Các miếng xốp đã nghiền nát được đưa vào máy nóng chảy tạo bọt mà chúng tôi còn gọi là máy làm đặc bọt. trong chất cô đặc nóng chảy, vật liệu xốp bị nóng chảy khi đun nóng thành trạng thái nóng chảy. Thể tích của bọt tiếp tục giảm đáng kể trong quá trình này (thường từ 40 đến 60 lần thể tích ban đầu), giúp việc bảo quản và vận chuyển dễ dàng hơn.

Hình thành hoặc chặn - để sử dụng tiếp theo

Bọt nóng chảy có thể được làm nguội và đúc thành khối xốp hoặc các dạng rắn khác. Những bọt đúc này có thể được sử dụng làm nguyên liệu thô công nghiệp và được sử dụng rộng rãi trong sản xuất các sản phẩm nhựa tái chế, vật liệu xây dựng, vật liệu cách nhiệt, v.v.

Lưu trữ và vận chuyển

Do thể tích bọt giảm đáng kể sau khi nóng chảy nên vật liệu xốp đã qua xử lý tái chế dễ dàng bảo quản và vận chuyển, đồng thời có thể vận chuyển đến các nhà máy để xử lý tiếp theo với chi phí thấp hơn nhiều.

Ý nghĩa to lớn của việc tái chế pallet xốp

- Giảm ô nhiễm: Bọt có chu kỳ phân hủy dài, thông qua tái chế cơ học có thể làm giảm ô nhiễm môi trường.

- Cải thiện việc sử dụng tài nguyên: Chuyển đổi bọt thải thành nguyên liệu thô có thể sử dụng, tiết kiệm tài nguyên.

- Hỗ trợ nền kinh tế tuần hoàn: Tái chế bọt giúp giảm sự phụ thuộc vào nhựa nguyên sinh và thúc đẩy sự phát triển bền vững.

- Giảm chi phí vận chuyển: Nhiệt hạch làm giảm đáng kể khối lượng, giúp việc vận chuyển hiệu quả hơn.

Thông qua quy trình tái chế pallet xốp này, những pallet xốp đã qua sử dụng có thể được biến đổi từ rác thải thành tài nguyên quý giá, góp phần bảo vệ môi trường và nền kinh tế tuần hoàn.