Waste tire recycling line | rubber granules making machine

Waste tire recycling line | rubber granules making machine

The waste tire recycling line (also rubber powder production line) uses advanced tire recycling technology, and used tire recycling equipment, making the waste tires into rubber powder. The waste tyre recycling line mainly includes a tire ring cutter, strip cutter, lump cutter, and rubber granules machine. The size of rubber particles is different, which will meet customers’ requirements. The materials recycled by the waste tire recycling machine have multiple uses and sales channels, which have outstanding advantages.

What is the best method to recycle used tires?

With the development of the auto industry, the amount of waste tires has been on growth. Because of the strong resistance of the heat, it is not an easy thing to decompose waste tires. Used tires not only always occupy a lot of land but spread diseases by breeding mosquitoes.

Reused waste tires directly as fish shelter or floating lighthouse. but this method is not popular. Thermal decomposition is also a good way to recycle used tires, but the recycling cost is too high without much profit. Recycling waste tires into rubber powder by the waste tire recycling line is widely used in many countries, which is regarded as the most reasonable way to recycle used tires. What’s more, the reclaimed rubber industry is keeping an upward momentum.

Recycling process of the waste tire recycling line

Cutting the tire side

For cutting the tire side, we can use the ring cutter. This used tire recycling equipment is used for cutting and separating the steel mouth, sidewall, and crown of used tires, and is the first process for recycling used tires.

The basic principle is to select the inner ring of the tire as the support point and the inner ring on the support frame. Move the tool while the tire is running at low speed, cut it into the tire, and cut the tire smoothly.

Cutting the tire into strips

This strip cutter can cut the tire when removing wire into strips. This rubber tire cutting tool is simple, reasonable in design. The width of the strap is adjustable, two-disc knives are made of special metal heat treatment, which is hard and durable and can be used repeatedly.

Cutting the tire strips into lumps

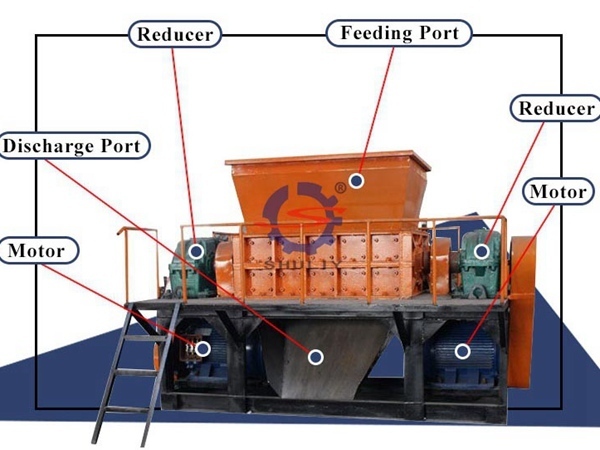

The lump cutter is mainly used to cut rubber strips into pieces of a certain size. The blades are made of alloy, when blades are not sharp enough, they can be sharpened repeatedly. This machine is affordable, easy to operate, and environment friendly, it is durable and pollution-free.

Granule making and screening

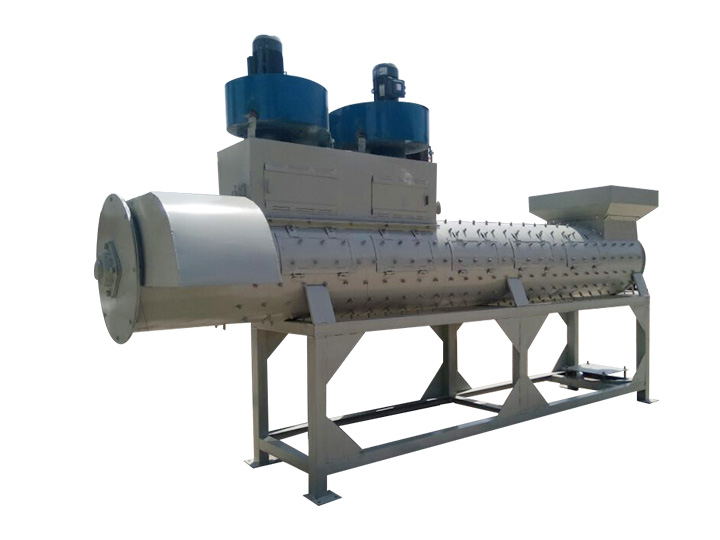

The rubber lumps will be crushed by the crusher machine two times in the waste tire recycling line. In order to improve the quantity of the rubber granules, we crush the rubber lumps roughly for the first time, then grind them more finely. Rubber particles will be sent to the screening table.

Full and effective pulverization can be obtained in the crushing chamber. This new type of waste rubber granules machine has high output, low energy consumption, high efficiency, and uniform discharge.

Wide application of rubber powder

After the above steps in the waste tire recycling line, the waste rubber will be recycled into rubber powder, which has a really wide usage. More and more tire recycling equipment manufacturers prefer to use recycled rubber powder instead of other raw materials to save costs and improve performance.

- To begin with, rubber powder can be used in concrete manufacturing in the construction industry, a certain proportion of rubber powder can be added to enhance the effect of elasticity.

- Secondly, rubber powder made from waste truck tires can be used to make special materials, for example, stealth aircraft. Because of the function of absorbing radar waves, rubber powder is a rare and inexpensive material.

- Additionally, the rubber powder sprayed on the chassis of cars, racing cars, off-road vehicles can greatly enhance elasticity and reduce noise. It can protect the service life of the car, increase comfort, and protect human health.

- Another application for rubber powder is paving the road. The antioxidant in the rubber powder can slow down the aging process of road surfaces.

- Rubber powder can also be used to make sports venue materials. The bouncy ground can keep minimize injuries during exercise and help players have a better grade.

Features of waste tyre recycling line

- Waste tire granulator machines are easy to operate and have stable performance.

- We use the advanced waste tire pellet machine to make rubber granules at room temperature.

- The structure of waste tire recycling line is very compact, only occupied a small area.

- Low energy consumption and easy to maintain.

Automatic waste tyre recycling line video

Waste tire rim separating and cutting machine

Waste tire recycling line services

- Our delivery time is one month, from the receipt of an order to the goods arrive at the port.

- The goods will be dispatched on time, and customers can check the logistics information during the transportation.

- When customers receive the goods, we will offer machine instructions and installment videos. We can also offer a live stream or organize our engineer to your plant to instruct.

- Except for wearing parts, quality assurance within one year, lifetime maintenance.

- Our company’s integrity management, quality assurance, welcome to consult and negotiate.

Our factory of the rubber powder production line

Hot Product

Plastic Bag Shredder Grinder Machine

A plastic bag shredder is a kind of…

PET bottle label remover recycling machine

PET bottle label remover is indispensable for plastic…

EPE EPS Foam Granulating Line

The EPS foam granulating line is suitable for…

Plastic film cold washing rinsing tank

The rinsing tank is used for rinsing the…

Horizontal Styrofoam Shredder

A horizontal styrofoam shredder is mainly used to…

Belt climbing conveyor | Inclined transport machine

A belt climbing conveyor is an essential machine…

Rigid Plastic Shredder Machine

Shuliy rigid plastic shredder machine is also called…

Cotton Waste Recycling Machine | Garment Rags Tearing Machine

The cotton waste recycling machine is mainly used…

PET Bottle Crushing Machine

PET bottle crushing machine plays a very important…