What do you know about water ring pelletizer?

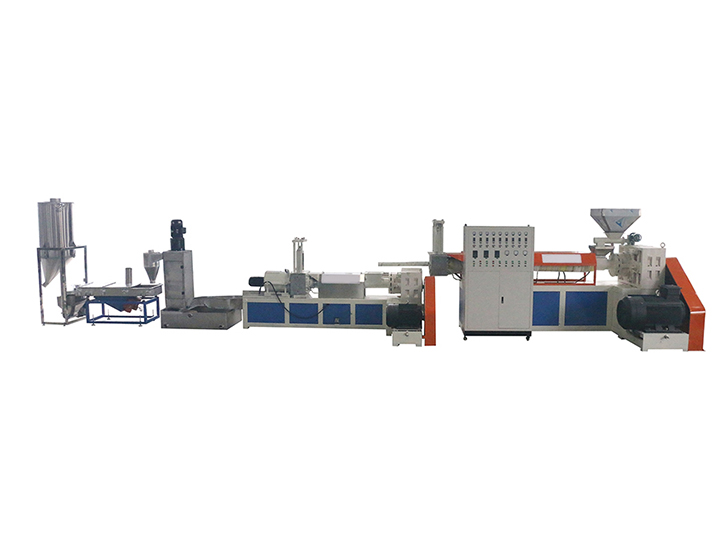

Brief introduction of water ring pelletizer

The working principle of the traditional waste plastic recycling granulator is to melt and filter the plastic through a single-stage or two-stage extruder, extrude the strands, and then cool and solidify and then cut into pellets. The water ring pelletizer is a new type of machine that directly cuts pellets when the melted plastic is extruded from the die surface when it is in contact with cold water, and the pellets obtained are more uniform in size and better in color.

Differences between water ring pelletizing and traditional pelletizing?

Water ring pelletizing is a kind of pelletizing, which is a brand-new form of pelletizing that breaks through the traditional stretch water-cooled pelletizing.

The tranditional water-cooled granulation is mainly suitable for some conventional plastics with average value and good stretch performance. However, with the rapid development of polymer materials, the variety, performance and value of recyclable plastics have undergone great changes. At this time, die face cutting technology, as a new type of imitation new material granulation technology, has become more and more popular by major users.

The advantages of water ring pelletizing

- High particle density and good fluidity;

- Eliminate the oxidation of particles;

- Less bonding phenomenon;

- Optimize the shape of the particles, the surface of the particles is smooth and uniform, such as water droplets or spherical;

- More convenient operation mode;

The disadvanges of water ring pelletizing

- There are many supporting equipments, and the operation technology requirements are high. It is more suitable for specific users, and ordinary users can simplify the configuration.

- The equipment investment budget should be relatively high.